Bitumen cap sheet

What is Bitumen cap sheet?

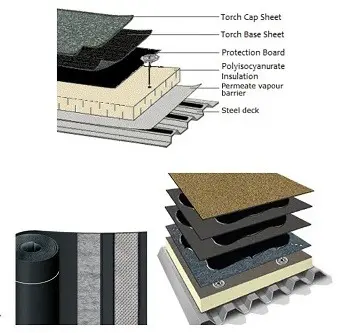

Bitumen cap sheet on the roof is made of the top layer of bituminous felt glued to the middle layer below and often covered with foil chips and reinforced fibers. Roofing felt also known as reinforced bitumen membranes (RBMs) and also On low pitched roofs such as built up roofs (BUR) or modified bitumen roofs, cap sheet is used to create a waterproof surface. Constant exposure to wind and weather can cause the BUR roof to become brittle and crack, then water can seep into the cracks and eventually into the building. The cap sheet covers and protects the layers below it and helps to increase the lifespan of the roof.Description cap sheet

Bitumen cap sheet is created from several layers of materials, including layers of asphalt or fiberglass with a bitumen coating. It is often coated with some type of mineral granules for strength and durability. This is a fairly heavy type of roofing material and is often referred to as a 90-pound roof because of its approximate weight of a standard square. Of course, it is worth noting that technology and improvements have reduced the weight of several products, many of which weigh around 72 pounds. The more roof layers and cover sheets are built, the more effective the roof is in resisting leaks.Methods of applied Cap sheet to the roof

- Thermal welding to connect the sheets to each other and to the roof below.

- Apply cement or asphalt between the layers to hold everything together.

- And depending on wind levels, some professional roofers use a layer of sand on top to help reduce the weight of the product.