Bitumen 85/25, characterized by its sol structure, undergoes a semi-hardening process through vacuum fractionation under oxidation or air blowing. This involves passing air through heated bitumen to achieve the desired viscosity, resulting in a flexible yet non-flowing bitumen at ambient temperatures. The air-blowing process modifies viscosity, leading to variations in equilibrium.

Applications of Bitumen 85/25

Usage of Bitumen 85/25 finds extensive across diverse industries:

- Chemical and Fuel: Used as a component in chemical and fuel production.

- Paints, Lacquers, and Varnishes: A key ingredient in the formulation of paints, lacquers, and varnishes.

- Paper-Pulp-Board and Textile Processing: Employed in the manufacturing processes of paper, pulp board, and textiles.

- Road Construction and Pavement: Integral in the construction of roads and pavements.

- Crack Seal and Repair: Used for crack sealing and repair work.

- Civil Works and Roofing: A crucial component in civil engineering projects and roofing.

- Construction Industries: Widely utilized in various construction applications.

- Sealing and Insulating Buildings: Acts as a sealant and insulating agent for buildings.

- Adhesive and Additive: Used as an adhesive and additive in construction materials.

- Dust-Binding and Coating: Employed for dust-binding and coating purposes.

- Flooring and Insulating Agent: Used in flooring applications and as an insulating agent.

- Production of Rubber and Plastic Products: An essential component in manufacturing rubber and plastic products.

- Paving and Roofing: Commonly used in paving and roofing projects.

- Asphalt-Based Paints: Included in the formulation of asphalt-based paints for corrosion protection.

- Lining Public Works Structures: Used for lining structures in public works projects.

- Adhesives in Electrical Laminates: An ingredient in adhesives used in electrical laminates.

- Base for Synthetic Turf: Utilized as a base material for synthetic turf.

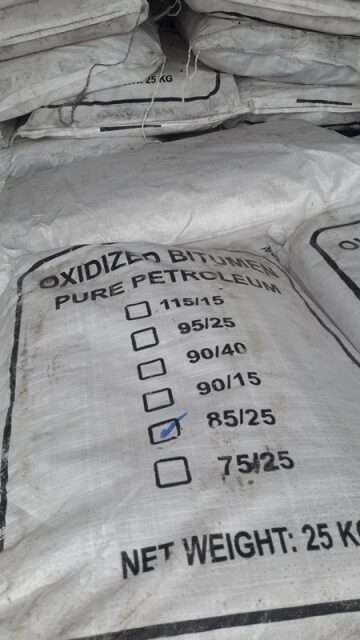

Packing of Bitumen 85/25

ATDM, as a manufacturer of blown asphalt, offers Bitumen 85/25 in various packing options, including kraft bags, meltable plastic bags, drums, and bulk packaging. The process involves controlled air blowing of penetration-grade bitumen until the specified softening point and penetration ranges are achieved. The oxidized bitumen grade 85/25 complies with ASTM standards and specifications.

Quality Assurance

ATDM provides a guarantee of the quality of Bitumen 85/25 by arranging international inspectors to oversee quality and quantity during each shipment’s loading. Rigorous quality control measures, including batch test reports, are employed before shipping to ensure compliance with ASTM/EN 13304:2009 standards.

Bitumen 85/25 Specification

| Property | Specification | Test Method |

|---|---|---|

| Specific Gravity @ 25/25 | 1.01/1.06 | ASTM D-70 |

| Penetration @ 25°C | 20/30 | ASTM D-5 |

| Softening Point (°C) | 80/90 | ASTM D-36 |

| Loss on Heating (%) | 0.2 Max | ASTM D-6 |

| Flash Point (°C) | 250 min | ASTM D-92 |

| Solubility in CS2 (%) | 99.5 Max | ASTM D-4 |

| Spot Test | Negative | A.A.S.H.O T102 |

In summary, Bitumen 85/25 stands as a versatile material, finding applications across numerous industries for its unique properties and adaptability. ATDM ensures the highest quality standards, making it a reliable choice for various construction and manufacturing needs.