What is Gilsonite?

Gilsonite is a shiny black, brittle substance found in vertical veins within the earth, also known as natural asphalt resinous and brittle and glossy shape found in southern Turkey since the 1930.

Solubility of Gilsonite

It is naturally rich in hydrocarbons and soluble in aliphatic and aromatic solvents, making it extremely versatile.Generally it is a hard hydrocarbon and is often refer to as a Gilsonit, natural hydrocarbon, asphaltite, uintaite, or asphaltum. It is soluble in both aromatic and aliphatic solvents, as well as petroleum asphalt.

Optimise Drilling Fluid Formulations

In the realm of oil and gas exploration, Gilsonite plays a crucial role in optimizing drilling fluid formulations moreover it is unique composition contributes to the stability and lubricity of the fluid, resulting in smoother drilling operations and prolonged equipment lifespan.

Increase Performance in Asphalt

One of Gilsonite’s key industrial uses is to harden softer petroleum products such as petroleum asphalt and various bituminous blends. When blended, Gilsonite improves durability, increases the softening point, and enhances the overall performance of asphalt and coating formulations.

ATDM Company provides high-purity Gilsonite products that are specially processed to:

Reinforce softer petroleum-based binders

Enhance resistance to deformation, UV, and water

Improve adhesion and longevity in road and roofing applications

As a natural and cost-effective additive, Gilsonite is an ideal solution for industries looking to strengthen and stabilize their petroleum-based products and formulations.

Quality Boost in Manufacturing

Manufacturers turn to Gilsonite to enhance the quality and durability of their products, particularly in paints and coatings. The addition ensures a resilient finish that withstands environmental factors, providing long-lasting results.

Cost-Effective Solutions

Its ability to enhance the performance of materials allows businesses to optimize their budgets while ensuring maximum value for their investment.

Environmentally Friendly Option

Embracing sustainability, it is really stands out as an environmentally friendly option thus as a natural resource, it minimizes the environmental impact associated with some synthetic additives.

Turkey Gilsonite

In Turkey, where Gilsonite mines are found, it is known locally as Bitumkaya or Kaya Asfalt, meaning bitumen stone. In addition molecular weight is about 1500, and its softening temperature varies from 200 to 450 F, depending on the age and composition of the mine. Its composition is about 86% carbon, 11% hydrogen, and 3% nitrogen.

American Gilsonite

It is found in large quantities primarily in the Uintah Basin of northeastern Utah, USA. The basin’s unique geological makeup allowed for the preservation and concentration of this rare material.

History of finding

It is dates back to the early 1860 when it was first discovered. However, it was not until the mid-1880s that Samuel H. Gilson began to promote it as a waterproof coating for wooden pilings, insulation for wire cable, and a unique varnish. His promotion was so successful that in 1888, he and a partner formed the first company to mine and market it on a commercial scale.

Iran Gilsonite

Gilsonite powder

As a prominent Gilsonite powder factory and mine owner, our operations boast a substantial monthly capacity of 10,000MT of lump and 3,000MT of powder, covering a mesh range from 10 to 200 and up to 600 based on API EN ASTM standards. Employing state-of-the-art packing machinery, we ensure precision in packaging, offering a variety of options such as 50LBS multi-pager bags, 25Kg, 300Kg, 500Kg, and 1-ton jumbo bags. These packaging solutions are especially tailored for optimal use in fluid loss control in oil well drilling mud additives.

The Gilsonite Select

Originally, Gilsonite was sold as Selects and Fines with Selects commanding a higher price due to its better purity, good solubility, and usefulness in the paint, stain, and varnish industries. However, processing now removes most of the inert contaminants, and newer, more powerful solvents make the higher softening point grades more attractive to users. Today, It is graded by softening point and particle size, with all grades carrying a degree of quality far superior to those first marketed in the 1880s.

Compatibility

The adaptability of Gilsonite as a natural resource extends across various industries, showcasing compatibility with a diverse range of materials. It seamlessly integrates with Microcrystalline and Paraffin Waxes, Petroleum Resins and Oils, Rosins, Tall Oil Pitch, Vegetable Oils (such as Linseed and Soya), Petroleum Process Oils, and Petroleum Asphalts. This broad compatibility underscores Gilsonite’s role as a versatile component with applications spanning different sectors.

Applications

- Asphalt and Pavement: generally special grade of Gilsonite is use in the production of asphalt and pavement to improve its strength, durability, and resistance to water and chemicals.

- Oil and Gas Drilling: It is using as an additive in drilling fluids to control viscosity, prevent fluid loss, and reduce friction during drilling.

- Foundry and Steel Industry: It is using as a carbon additive in the production of iron and steel to improve the quality and strength of the material.

- Ink and Paint Industry: It is using as a black pigment in the production of ink and paint due to its unique color and ability to resist heat and chemicals.

- Adhesives and Sealants: As a binder in the production of adhesives and sealants due to its ability to provide high adhesion and resist water.

- Carbon Products: Meanwhile a raw material in the production of carbon products such as carbon black, electrodes, and battery anodes due to its high carbon content.

- Concrete Industry: A plasticizer in the production of concrete to improve its workability and durability.

- Agriculture Industry: working as a soil amendment and plant nutrient to improve soil quality and increase crop yields.

API mesh size

+35 (500 MICRONS) = 0.1

+65 (212 MICRONS) = 2.0

+100 (150 MICRONS) = 8.0

+200 (74 MICRONS) = 25.0

Global Gilsonite price

The price of Gilsonite is affected by various factors. One of the major factors is weather conditions, such as rainfall, which can impact mining operations and affect the supply , leading to changes in its price. In addition, the international market prices of petroleum commodities like crude oil and bitumen can also have an impact on the price of Gilsonite, as they are closely related products. Market conditions, such as supply and demand, production costs, and competition, also play a significant role in determining the price.

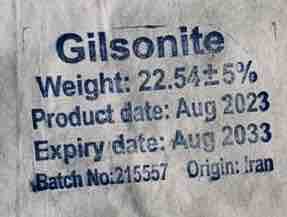

Packing of Gilsonite

With special machinery our tolerance of packing weight in packing of Gilsonite powder is in recyclable bags, such as 25Kg or 50lbs multi-paper bags on pallets that are shrink-wrapped with plastic or wooden pallets. Each pallet can carry up to 34 bags, and there are typically 20 pallets per 20ft container, therefore with a maximum weight of 28.8MT per 40ft container. In the meantime other packaging options include jumbo bags of 1000Kg or 25 and 50Kg polypropylene bags and the craft bags are recyclable and preferred by most oil companies.

Physical Specification

Naturally occurring mineral that is initially in a chunk form and then pulverized into various mesh sizes using machines. Due to its fragile nature, the material shatters easily, and the best particle distribution is obtained by rolling the material between two drums. Eventually this pulverized form of Gilsonite is used as a raw material in various industrial sectors.

Physical Properties

It has a number of distinctive physical characteristics that make it easy to identify and ideal for specific uses:

| Property | Description |

|---|---|

| Appearance | Shiny black, resin-like solid |

| Texture | Brittle and can be easily crushed into a fine powder |

| Fracture | Conchoidal (smooth, curved breakage) |

| Luster | Glossy or vitreous (glass-like) |

| Melting Point | Ranges between 165°C and 220°C |

| Density | Approximately 1.04 to 1.06 g/cm³ |

| Solubility | Insoluble in water but soluble in organic solvents (e.g., aromatic and aliphatic hydrocarbons) |

| Color | Deep black with a shiny surface when fractured |

These physical properties allow Gilsonite to be easily processed, transported, and blended with other materials for commercial use.

Chemical Properties

The chemical makeup of Gilsonite contributes greatly to its performance in various applications:

Hydrocarbon Content: Composed primarily of complex, high molecular weight hydrocarbons.

Carbon Content: High fixed carbon percentage, typically over 85%.

Volatile Matter: Contains a moderate amount of volatile components, which can evaporate at elevated temperatures.

Sulfur and Nitrogen: Contains small amounts of sulfur (~0.3–2%) and nitrogen, depending on the source.

Ash Content: Very low ash content (<5%), which is beneficial in high-purity applications like inks and paints.

pH Stability: Chemically stable across a broad pH range, making it resistant to acidic and basic environments.

Oxidation Resistance: Gilsonite has relatively good resistance to oxidation, which increases the longevity of products made with it.

Solubility of Gilsonite

This product is a hydrocarbon and has moderate solubility in solvents. It is more soluble in kerosene and naphtha and also in crude oil. When Gilsonite is mixed with cement, the effect of crude oil on the set cement is negligible beyond the dissolution of exposed particles. It has a melting point of 385°F, and some softening occurs above 240°F, causing particles to fuse together. It can be used in wells with a static bottom-hole temperature of 300°F or slightly higher due to the temperature reduction during circulation.

Ash content

Impurity of Gilsonite called ash and the content showing density and solubility which can vary depending on the source and processing method, but typically ranges from 5% to 26%. Ash content is the inorganic residue that remains after the organic matter in Gilsonite has been burned off. It can consist of minerals and other impurities that are present in the original rock material from which the Gilsonite was formed, as well as any contaminants that may have been introduced during mining or processing.

Liquid Gilsonite

Water base drilling mud services companies require liquid Gilsonite, which is specially formulated to be used in most water-based systems and is highly effective in lignosulfonate, potassium, and also PHPA polymer mud systems. The product is readily dispersible, allowing for easy addition of high concentrations to the mud system.

TDS of Gilsonite analysis

TEST METHOD | RESULT | TEST NO |

ASTM-D3174 | 1-10% | ASH CONTENT,WT% |

ASTM-D3173 | 1% | MOISTURE CONTENT,WT% |

ASTM-D3175 | 63 | VOLATILE MATTER,WT% |

ASTM-D4 | 80-90 | SOLUBILITY IS CS2,WT% |

ASTM-D3289 | 1.06 | SPECIFIC GRAVITY @25°C |

ASTM-D3279 | 79 | NORMAL HEPTANE INSOLUBLES,WT% |

— | BLACK | COLOR IS MASS |

— | BLACK | COLOR IN STREAK OR POWDER |

ASTM-D36 | 110-220 | SOFTENING POINT,°C |

ASTM-D6608 | 1.5% | SULPHUR CONTENT |

Download specification of Gilsonite

Download TDS of Gilsonite

Download MSDS of Gilsonite

FAQs:

- Is Gilsonite safe for the environment?

- Yes, Gilsonite is a natural resource and is considered environmentally friendly moreover to use need to check MSDS as well.

- Can Gilsonite be used in residential construction projects?

- While primarily used in industrial applications, Gilsonite can also find application in certain residential construction projects, particularly in road paving.

- What makes Gilsonite cost-effective?

- The Gilsonite’s cost-effectiveness stems from its ability to enhance material performance, reducing the need for frequent replacements and maintenance.

- Are there any specific precautions when handling Gilsonite?

- While generally safe, it’s advisable to follow standard safety measures when handling Gilsonite, including the use of protective equipment.

- Where can I purchase Gilsonite for my specific industry needs?

- Our Gilsonite is available through various importers and you can connect us to give you our distributor number locally.