Oil and gas additive

Oil and gas drilling fluids additive to control the viscosity, prevent fluid loss, and reduce friction during drilling. It can also improve the stability of the wellbore, reduce the risk of differential sticking, and help to prevent the collapse of the borehole.

Gilsonite can be added directly to the drilling mud or blended with other additives to create a custom drilling fluid that is tailored to the specific needs of the drilling operation. It is compatible with a wide range of other additives, including weighting agents, lubricants, and surfactants.

Working in oil and water base well

One of the key advantages of using Gilsonite as an additive in drilling fluids is its natural compatibility with both oil-based and water-based muds. This makes it a versatile choice for drilling in a variety of formations, including shale, sandstone, and limestone.

Drilling fluids

In addition to its use in drilling fluids, Gilsonite can also be used in the production of other oil and gas additives, such as emulsifiers and demulsifiers. Its unique properties make it an effective choice for these applications as well.

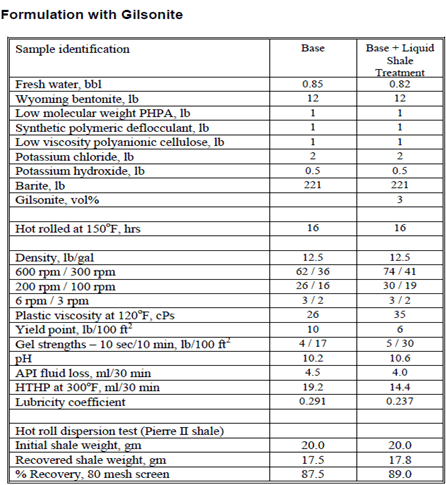

Formula of mixture Gilsonite with other drilling mud

Acceptable packing for oil and gas industry

lump form like rock packed in 500~1000kg jumbo bag

natural asphalt 200 mesh packed in 500~1000kg jumbo bag

300 mesh packed in 500~1000kg jumbo bag

30-40 mesh packed in 500~1000kg jumbo bag

100 mesh packed in 500~1000kg jumbo bag

300 mesh packed in 25kg pp bag

200 mesh packed 25kg multi paper bag

200 mesh gilsonite cementing packed 50lbs multi paper bag

30-40 mesh packed pp bag on pallet

Bulk on vessel

Specification and date sheet of the additive

TEST METHOD | RESULT | TEST | NO |

ASTM-D3174 | 5 | ASH CONTENT,WT% | 1 |

ASTM-D3173 | 1% | MOISTURE CONTENT,WT% | 2 |

ASTM-D3175 | 63 | VOLATILE MATTER,WT% | 3 |

ASTM-D4 | 81 | SOLUBILITY IS CS2,WT% | 5 |

ASTM-D3289 | 1.11 | SPECIFIC GRAVITY @25 C | 6 |

ASTM-D3279 | 79 | NORMAL HEPTHAN INSOLUBLES,WT% | 7 |

——————- | Black | COLOR IS MASS | 8 |

——————- | Black | COLOR IN STREAK OR POWDER | 9 |

ASTM-D36 | 210 | SOFTENING POINT,C | 10 |

ASTM-D5 | 0 | PENETRATION @25C | 11 |

ELEMENT ANALYSIS | |||

ASTM-D5291 | 84 | CARBON,WT% | 1 |

ASTM-D5291 | 7.1 | HYDROGEN,WT% | 2 |

ASTM-D5291 | 3.67 | NITROGEN,WT% | 3 |

ASTM-D5291 | 3.1 | OXYGEN,WT% | 4 |

LECO(S)ANALYZER | 4 | SULPHURE,WT% | 5 |