General description of petroleum jelly medical grade

Petroleum Jelly Medical grade is a mixture of natural waxes and mineral oils that together lock moisture in skin, moisturizing it to repair and relieve dryness. Medical-grade Petroleum jelly is made from the waxy petroleum material that formed on oil rigs and distilling it.

Petroleum jelly medial and pharma grade is a mixture of hydrocarbons, having a melting point usually within a few degrees of human body temperature, approximately 37 °C (99 °F). It is flammable only when heated to liquid; then the fumes will light, not the liquid itself, so a wick material like leaves, bark, or small twigs is needed to ignite petroleum jelly.

It is colorless, or of a pale yellow color (when not highly distilled), translucent, and devoid of taste and smell when pure. It does not oxidize on exposure to the air and is not readily acted on by chemical reagents. It is insoluble in water. It is soluble in dichloromethane, chloroform, benzene, diethyl ether, carbon disulfide and oil of turpentine

Manufacturing process of Medical PJ

Petroleum waxes are broadly classified into two types paraffin and microcrystalline. Paraffin waxes distill at temperatures less than about 8500F and are thus components of light paraffin distillates.

The higher boiling intermediates and heavy paraffin distillates and paraffin residual oils contain microcrystalline waxes. When light paraffin distillates are cooled, the wax separates in large, platelike crystals.

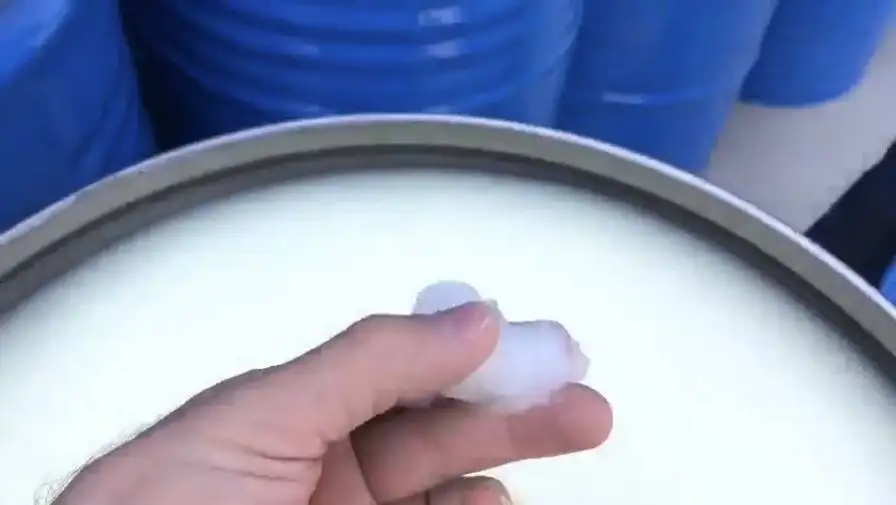

Cooling of the heavier distillates and residual oil does not produce obvious crystals; the wax separates as very small particles (micro crystals) which cause the oil to set to a paste or a jelly. A mixture of 30 to 50 percent heavy oil and microcrystalline wax forms petrolatum or petroleum jelly.

Petrolatum is a colloidal suspension of microcrystalline waxes in heavy oil with melting points ranging from 1100 to 1350F. 6 First of all, the ingredients are weighed as per the formulations. Now paraffin wax is taken in to reaction vessel with electrical heater (Jacketed).

Now micro crystalline wax is added in to reaction vessel. Both the waxes are then melted with continuous mixing and the temperature is maintained between 1200 – 1300 C. Now liquid paraffin is added with continuous stirring (150-200 rpm) at constant temperature, so that ingredients are mixed together to form emulsion or jell. The whole mass is cooled down and sample is taken for testing. After testing, material is packed in suitable containers The products would have to be manufactured as per standards laid down in IP, BP and such book of standards.

Uses

It is used all over the world to protect and heal dry skin, from dry, cracked hands to hard skin on heels, as well as for beauty purposes, like softening the lips or highlighting the cheekbones . Vaseline is used to protect and repair the skin. Vaseline is used for preventing diaper rash, but it can also be used to protect minor cuts and burns, to soften skin, and to lock in moisture in dry, cracked skin.

Packing

Medical-grade Jelly is packaged in new or used 180 kg drums, ISO tanks, and flexi tanks. Each 20-foot container accommodates 110 drums of petroleum jelly.

Guaranty/warranty of medical grade

petroleum jelly

ATDM guaranty the quality of medical grade Petroleum Jelly with arrangement of international inspector to check quality and quantity of petroleum jelly medical grade during the loading to vessel and controlling the production by QC by batch test report before shipping. ATDM guaranty the quality to meet with ASTM .

Analysis of medical grade

petroleum jelly

No | Characteristic | Result | Accepted limit | Method |

1 | Kinematic viscosity at 100 °c | 6.1 cst | 6-8 cst | Astm d-445 |

2 | Congealing point | 57 °c | 45-58 °c | Astm d-938 |

3 | Penetration consistency | 157 (0.1 mm ) | 140-160 (0.1 mm ) | Astm d-937 |

4 | Color (lovibond ) | 0.2 y | Max 0.5 y | Ip-17 method a 2 cell |

5 | Acidity or alkalinity | Passed | According to test method | B.p 2007 |

6 | Odor | Passed | Odour less when rubbed on hand | —- |

7 | Polycyclic aromatic hydrocarbons | Passed | Not more than absorbance of solution 6mg/l naphtalene in dmso @ 278 nm | B.p 2007 |