Description of asphalt sealant 115/15 90/40 85/25 95/25 90/10 85/25

Asphalt sealant, also known as asphalt sealer or pavement sealer, is a protective coating applied to asphalt surfaces, such as driveways, parking lots, and roads. The primary purpose of asphalt sealant is to protect the underlying asphalt from the damaging effects of water, sunlight, and chemicals, which can lead to deterioration and the formation of cracks.

Uses of asphalt sealant

In the construction of built up roofing as bonding or flood coats, asphalt 85/25 is used on inclines not exceeding 25% slope and 115/15 asphalt is used on inclines not exceeding 50%, and is preferred in high temperature areas due to its higher softening point.For corrosion resistance for pipe coating, steel structures, and in electric cable joint protection and industry.

Joint filling and sealant compound.

As an adhesive of building material.

For sound dampening felts and under carriage sealant in the automotive industry.

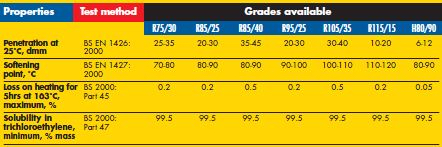

Standard of products

Our Asphalt sealant 85/25 115/15 90/40 complies with the requirements of B.S 3690: part 2, and ASTM D312, Type III & Type IV.Also comply with the Turkey National Building code (Vol. ll-Ch5) Tables No. 15 & 17.

There are two main products generally used for seal coating: coal tar sealers and asphalt emulsion coatings. The first one is cheaper but will require more product management when it is being applied.

Packing of material

Asphalt sealant is typically packaged in containers suitable for easy application. The packaging can vary based on the type of sealant and the manufacturer’s preferences. Here are some common types of packaging for asphalt asphalt sealer:

5-Gallon Buckets: Many asphalt sealants are available in 5-gallon buckets, which are convenient for smaller residential applications such as driveways. These buckets often have resealable lids to keep the sealant fresh between uses.

Bags: 25Kg bag, cartons and 200Kg drums.

55-Gallon Drums: For larger commercial applications, asphalt sealant may be supplied in 55-gallon drums. This bulk packaging is suitable for contractors or municipalities that need a larger quantity of sealant.

Pails: Smaller pails, typically ranging from 1 to 2 gallons, may be used for more targeted applications or for DIY projects where a 5-gallon bucket is more than needed.

Totes: Intermediate bulk containers (IBCs) or totes are larger containers that can hold several hundred gallons of sealant. These are often used for industrial or large-scale applications.

Spray Containers: Some asphalt sealants come in spray containers for easier application. These may be suitable for small touch-ups or for areas where a roller or squeegee is impractical.

When purchasing asphalt sealant, it’s important to consider the coverage area and the type of application equipment required. Additionally, follow the manufacturer’s guidelines and instructions for proper storage and application techniques to ensure the effectiveness of the sealant. Proper packaging and storage are essential to maintaining the quality of the sealant, as exposure to air and moisture can impact its performance.

Technical Specifications

Overusing sealer can cause peeling, flaking or cracking if it builds up. The industry standard is for sealcoating to be replaced every two years, which allows the asphalt sealant on your driveway or parking lot to wear away prior to resealing.