Manufacturer of bitumen 200/300

Bitumen 200/300 is a specific grade of bitumen characterized by its penetration range. The penetration grade indicates the hardness or softness of the bitumen, which directly influences its application. Bitumen with a penetration grade of 200/300 is relatively soft, making it suitable for certain climates and specific construction requirements. Its versatility and adaptability are among the key reasons for its popularity in the construction sector.

Flexi Bags for Bitumen

Flexi bags, also known as flexitanks, are flexible containers used for transporting liquids, including bitumen. These bags offer numerous advantages:

- Cost-Effectiveness: Flexi bags are often more economical compared to traditional packaging methods. They reduce the need for additional containers and packaging materials, lowering overall costs.

- Efficiency in Transportation: Flexi bags can be easily loaded into standard shipping containers, maximizing space utilization and reducing shipping costs.

- Ease of Handling: The flexible nature of these bags makes them easier to handle and transport, reducing the risk of damage during transit.

- Environmental Benefits: Flexi bags are reusable and recyclable, making them a more sustainable packaging option.

Jumbo Bags for Bitumen

Jumbo bags, also known as bulk bags or FIBCs (Flexible Intermediate Bulk Containers), are large, durable containers used for transporting bulk materials, including bitumen. The benefits of using jumbo bags include:

- High Capacity: Jumbo bags can hold large quantities of bitumen, making them ideal for bulk transportation.

- Durability: Made from robust materials, these bags are designed to withstand the rigors of transportation and storage.

- Cost Savings: Bulk transportation using jumbo bags can be more cost-effective due to reduced packaging and handling costs.

- Safety: Jumbo bags are designed with safety features to prevent spillage and contamination during transit.

Customizable Penetration for Bitumen

Customizing the penetration level of bitumen 200/300 is a crucial aspect of meeting specific project requirements. The process involves adjusting the bitumen’s hardness or softness to suit various climatic conditions and application needs. By offering customizable penetration, suppliers can ensure that the bitumen performs optimally in different environments, enhancing its usability and effectiveness.

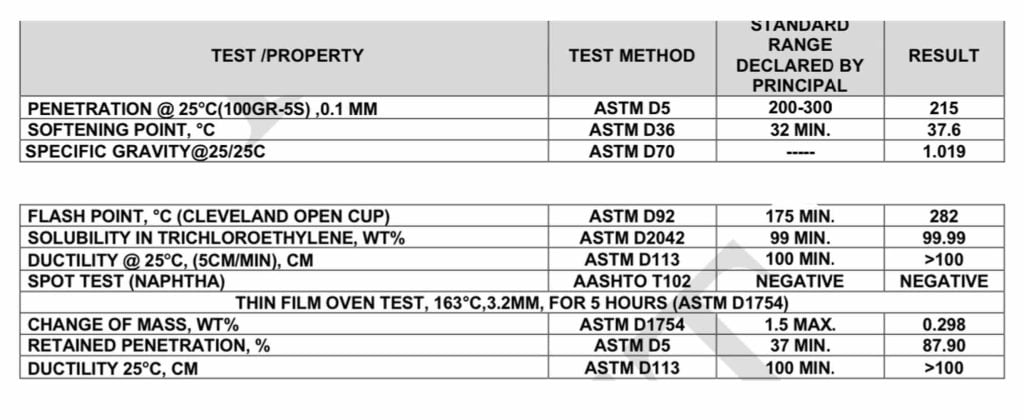

Specification and certificate of quality

The China Market for Bitumen 200/300

China’s rapid infrastructure development has created a substantial demand for bitumen. From road construction to waterproofing projects, bitumen 200/300 is widely used across various sectors. The need for high-quality, customizable bitumen is driven by the country’s diverse climatic conditions and the stringent requirements of modern construction projects. Understanding the unique demands of the Chinese market is essential for suppliers aiming to provide tailored solutions that meet local needs.

Packaging Solutions for Bitumen

When it comes to packaging bitumen 200/300, both flexi and jumbo bags offer distinct advantages. Comparing these packaging solutions helps in understanding their suitability for different transportation and storage needs:

- Flexi Bags: Ideal for liquid bitumen, providing flexibility and cost savings.

- Jumbo Bags: Suitable for bulk bitumen, offering high capacity and durability.

Each packaging option has its unique benefits, and the choice between them depends on specific project requirements and logistical considerations.

Handling and Transportation of Bitumen

Proper handling and transportation of bitumen are crucial to maintaining its quality and effectiveness. Best practices include:

- Temperature Control: Ensuring bitumen is stored and transported at the right temperature to prevent degradation.

- Secure Packaging: Using durable and secure packaging to prevent leaks and contamination.

- Efficient Loading and Unloading: Implementing efficient procedures to minimize handling time and reduce the risk of damage.

Quality Standards and Certifications

Maintaining high-quality standards and adhering to certifications is essential for bitumen suppliers. This includes compliance with international and local regulations, regular quality checks, and obtaining necessary certifications to guarantee the product’s performance and safety.

Environmental Considerations

Sustainability is a growing concern in the construction industry. Packaging and handling bitumen in an environmentally responsible manner include:

- Recyclable Packaging: Using packaging materials that are recyclable and reduce environmental impact.

- Efficient Transportation: Optimizing transportation routes and methods to minimize carbon footprint.

- Waste Management: Implementing effective waste management practices to handle bitumen residues and packaging waste.

Cost-Effectiveness of Packaging Options

Evaluating the cost-effectiveness of flexi and jumbo bags involves considering factors such as:

- Initial Investment: The cost of purchasing the packaging materials.

- Transportation Costs: Expenses related to shipping and handling.

- Reusability: The potential for reusing packaging materials to reduce long-term costs.

Innovations in Bitumen Packaging

Recent developments in bitumen packaging are focused on improving efficiency, safety, and sustainability. Innovations include:

- Smart Packaging: Incorporating technology to monitor and manage the condition of bitumen during transit.

- Enhanced Materials: Using advanced materials that provide better protection and durability.

- Sustainable Solutions: Developing eco-friendly packaging options that reduce environmental impact.

Supplier Selection for Bitumen 200/300

Choosing the right supplier for bitumen 200/300 involves considering factors such as:

- Quality Assurance: Ensuring the supplier adheres to high-quality standards and certifications.

- Customization Options: Availability of customizable penetration levels to meet specific project needs.

- Reputation and Experience: The supplier’s reputation and experience in the industry.

Case Studies

Examining success stories from the China market provides valuable insights into the effective use of bitumen 200/300. These case studies highlight best practices, innovative solutions, and lessons learned from real-life projects.

Challenges in Bitumen Packaging

Common challenges in bitumen packaging include:

- Temperature Control: Maintaining the right temperature during storage and transit.

- Leak Prevention: Ensuring packaging is secure to prevent leaks.

- Handling Efficiency: Implementing efficient handling procedures to minimize damage and waste.

Role of Technology in Packaging

Technology plays a vital role in enhancing the efficiency and safety of bitumen packaging. Innovations include:

- Monitoring Systems: Using sensors and tracking devices to monitor the condition of bitumen.

- Automation: Implementing automated systems for loading, unloading, and handling bitumen.

Market Trends and Forecast

The future of bitumen packaging in China looks promising, with trends indicating increased demand for sustainable and efficient packaging solutions. Key trends include:

- Sustainability: Growing emphasis on environmentally friendly packaging.

- Customization: Increased demand for customizable penetration levels.

- Technology Integration: Adoption of advanced technologies to improve packaging and handling processes.

Customization Requests

For projects requiring specific penetration levels, suppliers offer customization options to tailor the bitumen’s characteristics. This process involves:

- Consultation: Discussing project requirements with the supplier.

- Adjustment: Modifying the bitumen’s penetration level to meet the desired specifications.

- Testing: Conducting tests to ensure the customized bitumen meets performance standards.

Regulatory Framework in China

Understanding the legal requirements for bitumen packaging and transportation in China is essential for compliance. This includes:

- Local Regulations: Adhering to regulations specific to the Chinese market.

- International Standards: Ensuring compliance with international quality and safety standards.

- Certification: Obtaining necessary certifications to validate the product’s compliance and quality.

Partnerships and Collaborations

Strategic partnerships and collaborations play a crucial role in the success of bitumen suppliers. Benefits include:

- Resource Sharing: Pooling resources and expertise to improve product quality and efficiency.

- Market Access: Gaining access to new markets through partnerships with local firms.

- Innovation: Collaborating on research and development to drive innovation in bitumen packaging.

Logistics and Supply Chain Management

Optimizing the supply chain for bitumen involves:

- Efficient Logistics: Streamlining transportation and handling processes to reduce costs and improve efficiency.

- Inventory Management: Implementing effective inventory management practices to ensure timely delivery.

- Risk Mitigation: Identifying and mitigating risks in the supply chain to prevent disruptions.

Customer Service and Support

Providing excellent customer service and support is crucial for customer satisfaction. This includes:

- Responsive Communication: Ensuring timely and effective communication with customers.

- Technical Support: Offering technical assistance to address any issues related to bitumen handling and application.

- After-Sales Service: Providing support and services after the sale to ensure customer satisfaction and loyalty.

Safety Considerations

Safety is paramount in handling and transporting bitumen. Key safety measures include:

- Proper Training: Ensuring personnel are trained in safe handling practices.

- Protective Equipment: Using appropriate protective equipment to prevent accidents and injuries.

- Emergency Procedures: Having emergency procedures in place to handle spills and other incidents.

Bitumen Packaging Case Studies

Real-life examples of bitumen packaging provide valuable insights into effective practices and lessons learned. These case studies highlight:

- Innovative Solutions: Creative approaches to bitumen packaging and handling.

- Challenges Overcome: How challenges were addressed and resolved.

- Success Stories: Examples of successful projects and their outcomes.

Conclusion

The packaging and transportation of bitumen 200/300 for the China market involve numerous considerations, from choosing the right packaging solution to ensuring compliance with quality standards and regulations. Flexi and jumbo bags offer distinct advantages, and the ability to customize penetration levels enhances the bitumen’s versatility and performance. By focusing on quality, sustainability, and customer satisfaction, suppliers can meet the growing demand for high-quality bitumen in China, contributing to the country’s ongoing infrastructure development.

FAQs

How does bitumen 200/300 differ from other grades? Bitumen 200/300 has a specific penetration range, indicating its relative softness compared to other grades. This makes it suitable for certain climates and construction applications.

What are the advantages of using flexi bags for bitumen? Flexi bags offer cost savings, efficient transportation, ease of handling, and environmental benefits due to their reusable and recyclable nature.

Why are jumbo bags preferred for bulk bitumen transportation? Jumbo bags can hold large quantities of bitumen, are highly durable, and provide cost savings through reduced packaging and handling costs.

How can bitumen penetration be customized? Suppliers can adjust the hardness or softness of bitumen 200/300 to meet specific project requirements, ensuring optimal performance in different environments.

What are the key considerations for handling and transporting bitumen? Key considerations include temperature control, secure packaging, and efficient loading and unloading procedures to maintain quality and prevent damage.

What are the environmental benefits of using sustainable packaging for bitumen? Sustainable packaging options, such as recyclable materials and efficient transportation methods, help reduce the environmental impact of bitumen packaging and handling.