What is PBR Polybutadiene rubber?

PBR polybutadiene rubber containing a polymer obtained by block or graft polymerization of cis-1,4-polybutadiene with syndiotactic (syn)-1,2-polybutadiene, alone or blended with the other diene rubber, said syn-1,2-polybutadiene being crystallized and in a short fiber-like shape, and a breaking resistance characteristic and reinforcement characteristic being considerably improved by specifying the diameter and length of said short fiber, which is suitable for various parts of tire or industrial materials, and further relates to a composition of said polybutadiene rubber to which a carbon black is added for preferably used as a chafer or tread of tire, and still further relates to said composition to which a carbon black and an antioxidant are added for preferably used as a rubber blend composition for side wall.

High-Cis Polybutadiene rubber “ATDM 1220” is produced by a technology of solution polymerization based on Ziegler-Natta (Cobalt) catalyst. It has more than 96% of 1,4 Cis content and a very low glass transition temperature.

Cured “ATDM 1220” has excellent properties such as abrasion resistance, tear strength, resilience, weathering resistance, and low rolling resistance (good fuel economy) due to its low glass transition temperature (Tg typically <–90°C).

APPLICATION OF BUTADIENE RUBBER

ATDM 1220 is appropriate for rubber compounds used in the production of tires, floor coverings, footwear, children’s toys, rubber hose, belts, and golf balls.

Typical Physical Properties-Raw Materials¹

| Parameters Units Values Test methods | |||

| ML1+4@100? | MU | 41-49 | ASTM D1646 |

| CIS Content | WT% | MIN 96 | INTERNAL METHOD |

| Volatile Material | WT% | MAX 0.75 | ASTM D – 1416 |

| Ash Content | WT% | MAX 0.3 | ASTM D – 1416 |

Typical Properties- Compounds²

| Typical Properties | Units Values Test methods | ||

| Compound Mooney Viscosity | MU | MAX 77 | ASTM D – 1646 |

| Tensile Strength(35 Min) | Kgf/cm3 | MIN 150 | ASTM D412 |

| Elongation at Break (35 Min) | % | MIN 440 | ASTM D412 |

| 300% Modulus at 145 °C | |||

| 25 Min | Kgf/cm3 | 68-108 | ASTM D412 |

| 35 Min | 74-114 | ||

| 50 Min | 74-114 | ||

To each shipping lot/delivery a quality certificate including data on properties of the product determined during release

control is issued. Scope of the testing which is covered by the quality certificate is each time agreed upon in the sales contract.

² Compounding formula according ASTM D–3189.

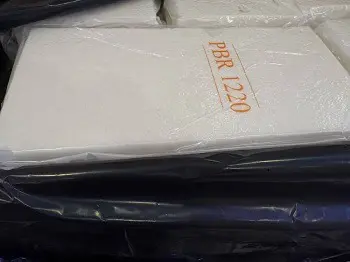

PACKAGING OF PBR BUTADIENE RUBBER

35 ±0.5 KG bales wrapped with polyethylene film.

36 bales per crate (1260±18 KG).

TRANSPORTATION OF BUTADIENE RUBBER PBR

ATDM1220 is typically transported in covered road trucks, in covered railway carriages and in standard shipping containers.

1220 is not a dangerous material to transport.

STORAGE OF BUTADIENE RUBBER

Product should be stored in sheltered conditions away from direct sunlight away from radiant heating elements and the temperature should not exceed 30°C.

DISTRIBUTOR OF BUTADIENE RUBBER

This document is of an informative character. The information given herein is based on the present state of our knowledge and experience. It makes neither product properties nor qualitative parameters guarantee and cannot be used as a basis of any claims.

The information provided cannot be used for any mixtures with any other substances. Product should be transported, stored and used in accordance with valid regulations and good occupational hygiene practice.

Making use of the information as well as product application is beyond the producer control and determination of the safe conditions of use is the sole responsibility of a customer.