What is cutback liquid bitumen?

Liquid bitumen is cutback asphalt used for cold weather bituminous road construction and maintenance. The distillates used for preparation of cutback bitumen are naphtha, kerosene, diesel oil, and furnace oil. There are different types of cutback bitumen like rapid curing (RC), medium curing (MC), and slow curing (SC)

Liquid bitumen is made by the addition of controlled amounts of petroleum extracts such as kerosene, naphtha, diesel oil, and furnace oil to perform as a solvent.

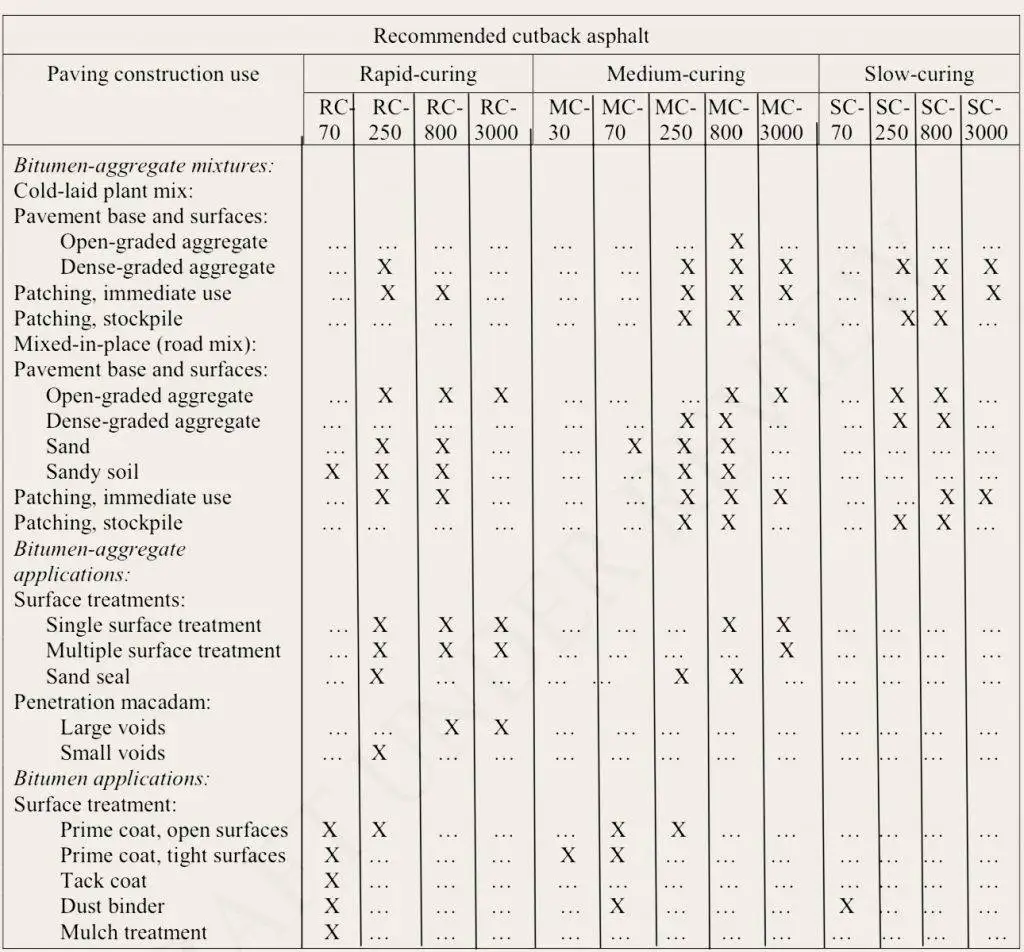

Usage of liquid bitumen for different propose

Liquid bitumen grades

Slow Curing often called \”road oils,\” are usually a residual material produced from the fractional distillation of certain crude petroleums. Traditionally any kind of aromatic, naphthenic and paraffinic oils are used. Slow Curing liquid bitumen materials can be prepared by blending bitumen with an oily petroleum fraction.

Medium Curing are a blend of Bitumen with lighter hydrocarbons such as kerosene.

Rapid Curing products are prepared with a light, rapidly evaporating diluent such as a naphtha or gasoline.

Differences of liquid bitumen and emulsion

Bitumen emulsion breaking process needs just 2 to 15 hours, however, cutback bitumen needs 48 to 72 hours to break. 8– Due to bitumen emulsion has ionic structure, it sticks to the aggregates or surface, but, cutback bitumen is neutral and just acts as a coat.

liquified MC30 MC 70 MC250 MC3000

In many places, Liquid bitumen use is restricted to patching materials for use in cold weather cutback MC-30 is medium curing (MC) cut-back asphalt consisting of penetration grade asphalt cement and diluent or cutter of medium volatility.The diluent temporarily reduces the viscosity of the asphalt cement for ease of handling and application.

After application the diluent evaporates, leaving asphalt cement to perform its function Petrochemical Trade Cutback MC-30 conforms to the specifications of ASTM D2127 (Medium-Curing Asphalt) or AASHTO M82The major use for Petrochemical Trade Cutback MC-30 is in the road maintenance industry where it is used as a prime coat of the base course prior to placing of the bituminous surface course. Its purpose is to bind the granular material of the base course to the asphalt layer. Usual application is by spray using a distributor.

RC GRADES

The specification for Rapid Curing (RC) Cutback Asphalts applies to liquid asphaltic materials in the form of asphalt cement combined with a petroleum solvent of a gasoline type. RC Cutback bitumen are specified by the following grades: RC-70, RC-250, and RC-800.Rapid Curing Cutback bitumen shall consist of asphalt cement which has been liquefied by blending with a gasoline type of petroleum solvent.

Slow Curing liquid Bitumen Specification

| Slow Curing (SC) | SC-70 | SC-250 | SC-800 | SC-3000 | Test Methods | ||||

|---|---|---|---|---|---|---|---|---|---|

| Property | Min | Max | Min | Max | Min | Max | Min | Max | |

| Kinematic viscosity at 60°C, mm2/s | 70 | 140 | 250 | 500 | 800 | 1600 | 3000 | 6000 | ASTM D-2170 |

| Flash point (Cleveland open cup), °C | 66 | – | 79 | – | 93 | – | 107 | – | ASTM D-92 |

| Distillation test: | ASTM D-402 | ||||||||

| Total distillate to 360°C, volume % | 10 | 30 | 4 | 20 | 2 | 12 | – | 5 | |

| Solubility in trichloroethylene, % | 99.0 | – | 99.0 | – | 99.0 | – | 99.0 | – | ASTM D-2042 |

| Kinematic viscosity on distillation residue at 60°C, mm2/s | 400 | 7000 | 800 | 10000 | 2000 | 16000 | 4000 | 35000 | ASTM D-2170 |

| Asphalt residue: | ASTM D-243 | ||||||||

| – Residue of 100 penetration, % | 50 | – | 60 | – | 70 | – | 80 | – | ASTM D-5 |

| – Ductility of 100 penetration residue at 25°C, cm | 100 | – | 100 | – | 100 | – | 100 | – | ASTM D-113 |

| Water, % | – | 0.5 | – | 0.5 | – | 0.5 | – | 0.5 | ASTM D-95 |

Medium Curing Cutback Bitumen Specification

Medium Curing Cutback Bitumen Specification

| Medium Curing (MC) | MC-30 | MC-70 | MC-250 | MC-800 | MC-3000 | Test Methods | |||||

| Property | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| Kinematic viscosity at 60°C, mm2/s | 30 | 60 | 70 | 140 | 250 | 500 | 800 | 1600 | 3000 | 6000 | ASTM D-2170 |

| Flash point (Cleveland open cup), °C | 38 | – | 38 | – | 66 | – | 66 | – | 66 | – | ASTM D-92 |

| Distillation test: Distillate, volume percent of total distillate to 360°C: | ASTM D-402 | ||||||||||

| to 225°C | – | 35 | – | 25 | – | 20 | – | – | – | – | |

| to 260°C | 30 | 75 | 10 | 70 | 5 | 55 | – | 40 | – | 15 | |

| to 316°C | 75 | 95 | 65 | 93 | 60 | 90 | 45 | 85 | 15 | 75 | |

| Residue from distillation to 360°C, percent volume by difference | 50 | – | 55 | – | 67 | – | 75 | – | 80 | – | |

| Tests on residue from distillation: | |||||||||||

| Viscosity at 60°C, Pa | 30 | 120 | 30 | 120 | 30 | 120 | 30 | 120 | 30 | 120 | |

| Ductility at 25°C, cm | 100 | – | 100 | – | 100 | – | 100 | – | 100 | – | ASTM D-113 |

| Solubility in trichloroethylene, % | 99.0 | – | 99.0 | – | 99.0 | – | 99.0 | – | 99.0 | – | ASTM D-4 |

| Water, % | – | 0.2 | – | 0.2 | – | 0.2 | – | 0.2 | – | 0.2 | ASTM D-95 |

Rapid Curing Cutback Bitumen Specification

| Rapid Curing (RC) | RC-70 | RC-250 | RC-800 | RC-3000 | Test Methods | ||||

| Property | Min | Max | Min | Max | Min | Max | Min | Max | |

| Kinematic viscosity at 60°C, mm2/s | 70 | 140 | 250 | 500 | 800 | 1600 | 3000 | 6000 | ASTM D-2170 |

| Flash point (Cleveland open cup), °C | – | – | 27 | – | 27 | – | 27 | – | ASTM D-92 |

| Distillation test: Distillate, volume percent of total distillate to 360°C: | ASTM D-402 | ||||||||

| to 190°C | 10 | – | – | – | – | – | – | – | |

| to 225°C | 50 | – | 35 | – | 15 | – | – | – | |

| to 260°C | 70 | – | 60 | – | 45 | – | 25 | – | |

| to 316°C | 85 | – | 80 | – | 75 | – | 70 | – | |

| Residue from distillation to 360°C, percent volume by difference | 55 | – | 65 | – | 75 | – | 80 | – | |

| Tests on residue from distillation: | |||||||||

| Viscosity at 60°C, Pa | 60 | 240 | 60 | 240 | 60 | 240 | 60 | 240 | |

| Ductility at 25°C, cm | 100 | – | 100 | – | 100 | – | 100 | – | ASTM D-113 |

| Solubility in trichloroethylene, % | 99.0 | – | 99.0 | – | 99.0 | – | 99.0 | – | ASTM D-4 |

| Water, % | – | 0.2 | – | 0.2 | – | 0.2 | – | 0.2 | ASTM D-95 |