SBR 1502

What is SBR 1502?

Styrene-Butadiene Rubber “SBR 1502” is produced by a technology of cold emulsion copolymerization based on soaps of rosin and fatty acids and contains 23.5% chemically bonded styrene.

SBR 1502 is a cold polymerized, 23.5% styrene SBR polymer made with a mixed-acid emulsifier, non-staining stabilizer, and salt-acid coagulation.1502 has very good properties such as process ability, abrasion resistance, less tendency to scorching.

SBR 1502 exhibits the excellent tensile strength, abrasion resistance, flexibility and recovery properties that are characteristic of “cold” rubbers.

uses of SBR1502

It is general-purpose rubber. Whatever it is widely used in tire, rubber technical, shoe, cable, and other industries for the production of automobile tires and tubes, a wide assortment of rubber technical articles, white and color shoes, cable and children’s toys castings, and so on.

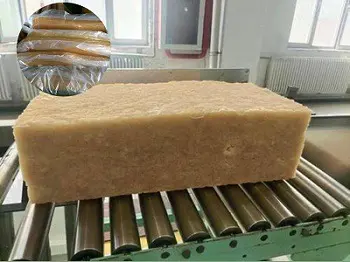

Packing of SBR

Normally it packed in 35 ±0.5 KG bales wrapped with polyethylene film, and in 36 bales per crate (1260±18 KG).

Shipping of product

At our company, this product is typically transported in covered road trucks, covered railway carriages, and standard shipping containers, and depending on the buyers’ destination, this product is harmless.

Storage of product

And also this product should be stored in sheltered conditions away from direct sunlight away from radiant heating elements and the temperature should not exceed 30°C.

Properties of SBR1502

| Typical Properties | Units | Values | Test method |

| Raw Mooney viscosity | MU | 46-58 | ASTM D |

| Volatile Material | % wt | < 0.75 | ASTM D |

| Ash Content | % wt | < 1.0 | ASTM D |

| Organic acids | % wt | 4.75-7 | ASTM D |

| Soaps | % wt | < 0.5 | ASTM D |

| Bounded styrene | % wt | 22.5-24.5 | ASTM D |

| Compound Mooney viscosity2 | MU | < 84 | ASTM D |

| Tensile strength (35 min cured)2 | Kg/cm2 | >250 | ASTM D |

| Ultimate elongation (35 min cured)2 | % | >350 | ASTM D |

| 300% Modulus (35 min cured)2 | Kg/cm2 | 167-207 | ASTM D |