What is bitumen 115/15

Bitumen 115/15 produce by injecting hot air and heating it, oxidization will start and the material become hard by spending energy and time.Our bitumen 115/15 is semi solid oxidized grade of pure petroleum bitumen categorized in polycyclic aromatic hydrocarbons and oxidized bitumen normally used for different purposes in the construction business.

Pure Bitumen 115/15 made by blowing hot air

In a process of thermodynamic and by hot air and heating up the material the bitumen will become hard and after spend time and energy we reach to Bitumen hard sealant 115/15.

sealant is containing: 1. Saturates 2. Aromatic 3. Resin 4. Asphaltens Since containing above material there is special properties of thermoplastic, adhesive, resistance to water and acid, alkalis.

Application of bitumen 115/15

a. Dam proof

Bituminous damp-proof modified with SBS can be cemented, for example, in a casting process with blown bitumen they are self-adheslve but they are sensitive to UV radiation and, therefore, as outer damp-proof courses, they must be provided with high protective layer. bitumen 115/15 courses modified with APP can be fixed neither with oxidation bitumen nor with elastomer impact adhesives~

b. Canal sealer

The proportion of bitumen 115/15 decreases towards the base course, but the coarse-grained fillers increase. However, the bitumen ensures the cohesion within the individual layers. During cutting as far as the asphalt base course, the laying channel is, then, dimensionally stable, with the result that no material caves in and the overall upper road structure remains intact.

c. Tennis court

A hybrid tennis court with one type of surface applied to one side of the net from the net to the back fence and a different type of surface applied to the other side of the net from the net to the back fence

d. Stockyard

The compositions are for use in a variety of environmental remediation barriers including fiber rolls, mats or blankets, and berms. Applications for the use of the compositions, devices, and methods include remediation of runoff water, of livestock waste, of eutrification of waterways, and for the revetment of banks

e. Paving

Traditional tack coats are often tracked away from the intended application area, generally by the tires of construction vehicles that are allowed to travel over the partially constructed structure, and deposited on other road surfaces. Tracking, i.e., the pick-up of bitumen 115/15 materials, is unsightly, damages the fresh asphalt film and results in less tack available to achieve maximum bond strength, leading to slippage and delimitation. This tracking can result in the existing pavement with little or no tack coat left in the wheel paths.

f. Railroad ballast

Typical binder contents in most asphalt mix designs range from 3 to 8 wt %. Stripping of the binder by the solvent is undesirable because this will result in decreasing the amount of binder in the asphalt mix, which will downgrade the asphalt quality and render it out of specification

g. Treatment and road beds

Rut mainly occurs in the upper layer of bituminous pavement.So adopt the better modified pitch of high bitumen 115/15 compound which has high-temperature stability making upper layer usually, this has improved the rutting resistance on road surface to a certain extent.But find that after deliberation even with the bituminous pavement of modified asphalt mixture making, rut still can occur after the driving use several years.

h. bitumen 115/15 backing carpet tile

The carpet tile is made by coating a thick layer of rubber-modified bitumen onto a secondary backing sheet. Then, a first precoat layer with hot melt petroleum resin or bitumen is applied. Next, a second layer made of hot melt bitumen mixed with a flexible vinyl adhesive, like ethylene vinyl acetate, is added to the fibrous back of the carpet. After that, the second layer is laminated onto the coated backing. As a result, the final carpet tile has strong dimensional stability, lies flat, and is easy to produce using an in-line method.

i. bitumen 115/15 for painting

Mixture of Bitumen 115/15 mixture with solvent high performance bitumen paint is an economical anti-corrosive, and protective solution on a wide range of common building materials especially iron, steel, timber and concrete, fibre reinforced cement panels & masonry. It produces a flexible quick drying coating which is waterproof, weatherproof and corrosion resistant.

Usage of bitumen 115/15

Usage of Bitumen 115/15 uses in the chemical, fuel, paints, lacquers, varnishes, paper-pulp-board, textile processing, road construction, pavement ,crack seal and repairmen, civil works, roofing, construction industries; sealing and insulating buildings, adhesive, construction materials additive, dust-binding, coating, insulating and impregnating agent, make rubber and plastic products. The bitumen 115/15 products are for paving, roofing; also used in asphalt based paints for corrosion protection of metals, in lining public works structures, adhesives in electrical laminates, base for synthetic turf; typical uses for bitumen115/15 include roofing, pipe coating, Portland cement pavement, hydraulic applications, paint manufacturing.

Bonding bitumen 115/15

Bonding bitumen compound is available in grade of 115/15 shape of bitumen blocks and using for joint seal also fixing bitumen roll sheet in case of damage or torn also adhesive of bonding material in different layer.

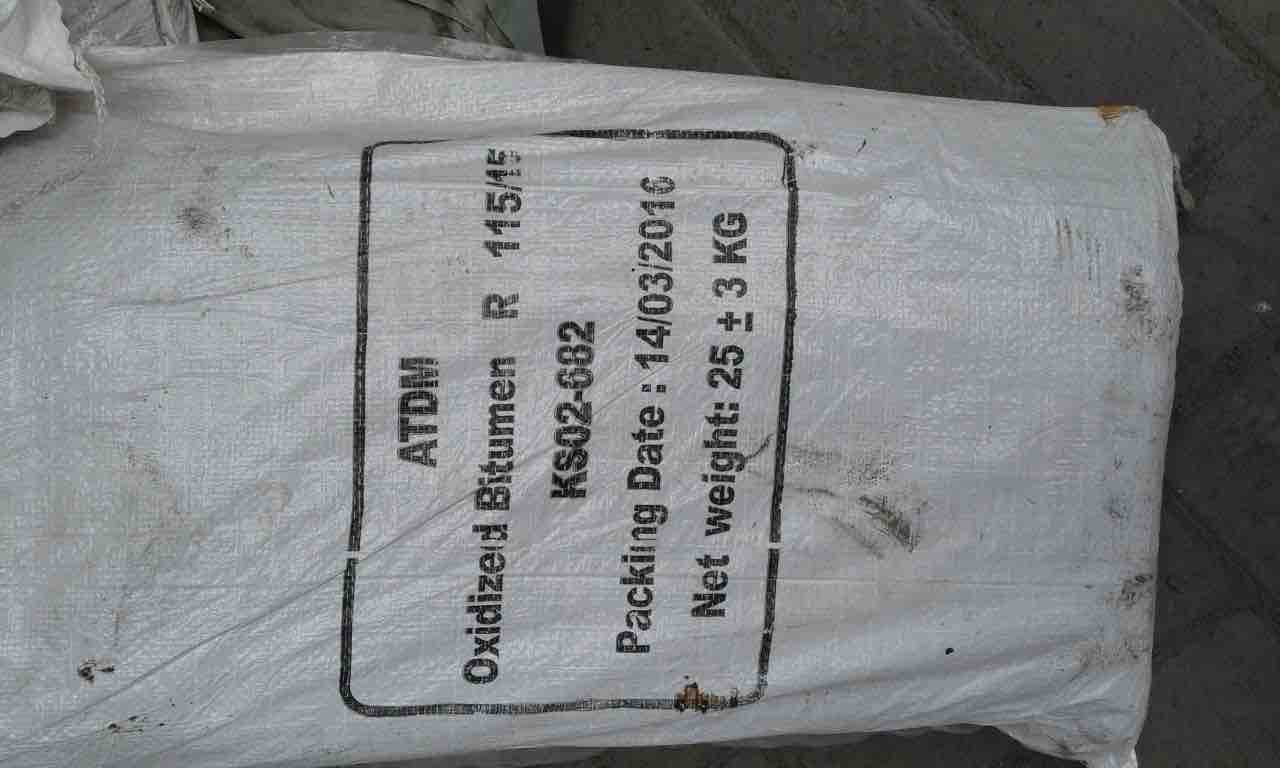

Packing of bitumen 115/15

The ATDM is manufacturer of bitumen 115/15 in various packing including kraft bag, meltable plastic bag, drum and bulk bitumen 115/15 from penetration grade bitumen, which is blown by hot air in a controlled process until the desired specification is reached. The ATDM bitumen 115/15 can be supplied in any grade and are designated by two numbers to indicate the softening point and penetration ranges. The blown asphalt grade 115/15 means softening point is 115°c and penetration is 15 desimillimiter is produced in compliance and conformity to ASTM standard and meets the following specification.

- Liner is none stick-able

- Carton on pallet 22.8 ton per 20ft container

- each carton is 25Kg with possibility of OEM for packing for customer

- all same weight and size

- able to pack in bag and arrange marking of customer on!

Specification of bitumen 115/15

|

Property |

Specification |

Test Method |

|

Specific Gravity @ 25/25 |

1.01/1.06 |

ASTM D-70 |

|

Penetration @ 25°C |

10/20 |

ASTM D-5 |

|

Softening Point (°C) |

110/120 |

ASTM D-36 |

|

Loss on Heating (%) |

0.2 max |

ASTM D-6 |

|

Flash Point (°C) |

250 min |

ASTM D-92 |

|

Solubility in CS2 (%) |

99.5 max |

ASTM D-4 |

|

Spot Test |

Negative |

A.A.S.H.O T102 |

Guaranty/warranty of bitumen115/15

Incorporating Bitumen 115/15 in construction projects ensures resilience, durability, and versatility. Whether it’s for road construction, dam-proofing, or creating robust tennis courts, Bitumen 115/15 proves to be an indispensable material. For high-quality Bitumen 115/15 adhering to international standards, choose ATDM as your trusted supplier.

Specification of oxidized bitumen 115/15

Download Oxidized Bitumen 115/15 specs to see detailed properties, technical data, and recommended industrial applications.

MSDS of oxidized bitumen 115/15

Download the MSDS for Oxidized Bitumen 115/15 to view safety guidelines, handling instructions, and detailed chemical and physical properties.

Bitumen 115/15 has a softening point between 110°C and 120°C, making it suitable for high-temperature applications such as waterproofing, roofing, and pipe coating.

It is widely used in roofing membranes, damproofing, pipe insulation, asphalt paving, carpet backing, and industrial sealants, thanks to its excellent thermal resistance and adhesive properties.

Bitumen 115/15 is ideal for hot and moderate climates due to its high softening point (110–120°C) and excellent thermal stability. It resists melting and deformation in high temperatures, making it perfect for use in tropical, desert, and arid regions.