Description of cellulose fiber

Cellulose Fiber is a blend of micro-cellulosic fibers for use in seepage loss control and other lost circulation needs. Unlike other seepage control materials, it has minimal effects on rheological properties and exhibits excellent return permeabilities.

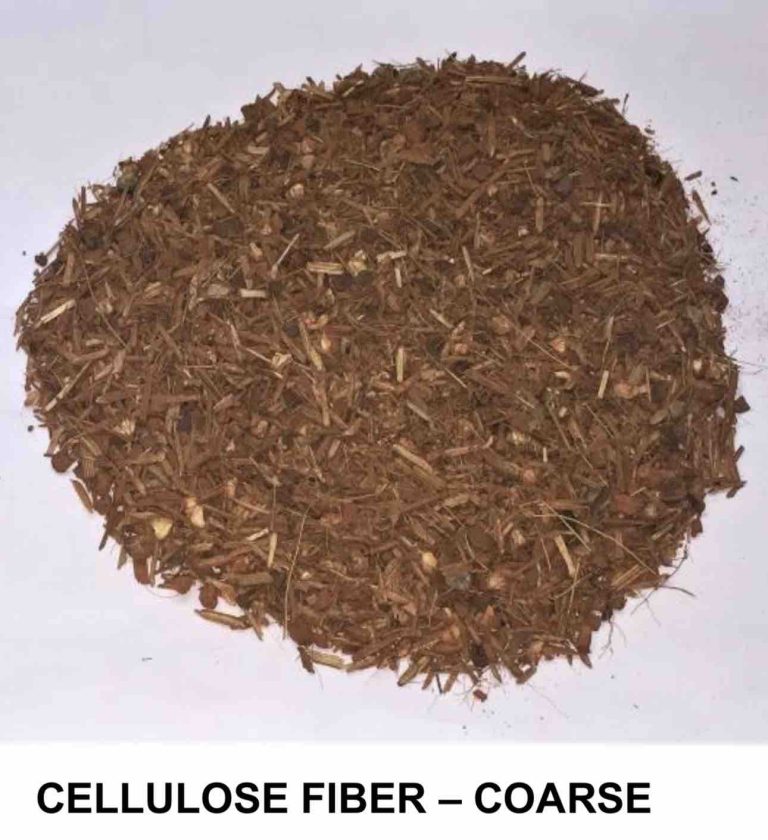

Appearance

Varies – Light tan to brown

Solubility

Insoluble

Particle / Grain Size

Available in Coarse, Medium and Fine grades

Advantages

- May be mixed rapidly through the mud hopper

- Does not require bypassing of most solids control equipment

- Seals off depleted zones without excessive build up of wall

cake

- Does not need addition of a wetting agent to go into oil based

fluids Is not treated with a wetting agent so it may be used in

water based fluids

- Unlike competitive materials does not appreciably increase

drilling fluid rheology

- Does not readily degrade due to shear

- Resistant to attack by bio-organisms

- Works in drilling fluids of any pH

- Compatible with other common lost circulation materials

- May be used in water base mud

Cost

The excellent return permeability and rheological properties which minimize the need for excessive dilution make Cellulose Fibre a superior, economical additive for seepage and lost circulation applications.

Mud Types

Water-based and oil-based muds

Mixing Requirements

May be mixed rapidly through the rig hopper

HS Code

11042900

Safety and Handling

Material must be handled as an industrial chemical, wearing protective equipment and observing the precaution as mentioned in Material Safety Data Sheet (MSDS).

Package

Packed in 25 lbs (11.3 Kg) paper sacks. Customised packaging and labelling is also available on request.