Industries worldwide need coatings that last longer, look glossier, and perform better. One of the most reliable solutions is mixing bitumen with PE wax. This blend combines the strength of oxidized bitumen 115/15 with the smooth, flexible qualities of polyethylene wax. The result is a durable, glossy compound ideal for waterproof coatings, roofing mastics, insulation membranes, and cable joint fillers. Because both materials are thermoplastic hydrocarbons, they mix easily under heat and give consistent performance. Moreover, bitumen with PE wax provides better gloss, flexibility, and flow compared to ordinary bitumen.

Why Mix Bitumen 115/15 with PE Wax

Oxidized bitumen 115/15 offers great hardness and a high softening point, but it becomes brittle in cold conditions. Adding polyethylene wax improves flexibility, surface smoothness, and shine. Furthermore, the wax reduces surface stickiness and makes application easier. Since both components share similar hydrocarbon structures, they stay stable for a long time. Consequently, bitumen with PE wax delivers higher durability and better visual appearance in all climates.

How the Blend Works

When heated to around 160–175 °C, oxidized bitumen melts first. Then the PE wax gradually dissolves and disperses evenly. This step improves elasticity and lowers brittleness. Meanwhile, the wax acts as a lubricant that allows the coating to level smoothly and form a shiny, even film. As a result, bitumen with PE wax offers better water resistance, higher gloss, and a softer, easier-to-apply texture.

Mixing Conditions (Industrial or Lab)

To produce consistent bitumen with PE wax, you must control both heat and stirring speed. First, melt the bitumen completely. Next, add 3–10 wt% PE wax slowly while maintaining a temperature between 160 and 180 °C. Continue mixing for 30–60 minutes at 200–500 rpm. Additives such as antioxidants or pigments can be introduced after the wax fully disperses. Always add the wax after melting to prevent overheating or uneven blending. Continuous agitation ensures a stable, uniform mixture suitable for all industrial uses.

Parameter | Recommended Range |

Temperature | 160–180 °C |

Bitumen Charge | Melt bitumen 115/15 fully |

PE Wax Addition | Add gradually (3–10 wt%) |

Mixing Time | 30–60 minutes |

Agitation Speed | 200–500 rpm |

Recommended Ratios

The ideal mix for waterproof coatings or mastics contains 3–7% PE wax. This proportion hardens the bitumen without losing flexibility. Too much wax (over 10%) can cause cracking on cooling. A proven industrial formula for bitumen with PE wax is 93% oxidized bitumen 115/15, 5% PE wax, and 2% additives. This mix produces a smooth, water-resistant compound with a flash point above 240 °C and penetration between 10–14 dmm.

Component | % by Weight |

Oxidized Bitumen 115/15 | 93% |

Polyethylene Wax (HDPE-based, mp ≈108 °C) | 5% |

Additives (antioxidants, fillers, pigments) | 2% |

Key Benefits of Bitumen–PE Wax Blends

Mixing bitumen with PE wax gives many advantages. The product becomes more heat-resistant and spreads more evenly. It produces a high-gloss surface and protects against moisture. The blend stays flexible even in cold weather, and its oxidation resistance ensures longer durability. Therefore, producers gain both higher performance and easier application in every project.

Typical Effects of Adding PE Wax

Adding PE wax raises the softening point by about 5–10 °C while slightly reducing viscosity at high temperatures. Gloss increases, water resistance improves, and the surface becomes smoother. However, if too much wax is used, flexibility drops. Keeping the PE wax content between 3–7% maintains the right balance between toughness and elasticity for consistent results in bitumen with PE wax systems.

Property | Effect |

Softening Point | +5 to +10 °C |

Penetration | Decreases (harder mix) |

Viscosity | Slightly reduced |

Gloss | Enhanced and smoother |

Water Resistance | Strongly improved |

Flexibility | Maintained up to −5 °C |

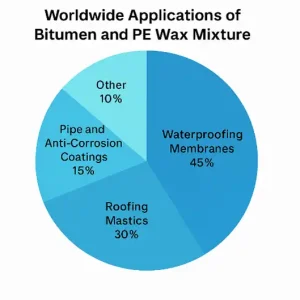

Applications in Industry

Bitumen with PE wax is widely used in roofing membranes, waterproof mastics, anti-corrosion pipe coatings, road-marking paints, cable compounds, and insulation layers. Because the blend melts cleanly and cools quickly, it supports continuous factory production. It also saves time, reduces rework, and improves finish quality. As a result, more manufacturers adopt this formula for large-scale infrastructure, construction, and protective coating projects.

Important Technical Notes

Keep temperature uniform at all times. Avoid overheating above 190 °C to prevent oxidation. Always keep water out to avoid foaming. For stronger adhesion, use oxidized PE wax (acid number 10–20). For higher shine and smoothness, select non-oxidized PE wax. Therefore, the right wax grade ensures that bitumen with PE wax performs perfectly under any application condition.

Example Industrial Mixing Procedure

To prepare a batch of bitumen with PE wax, heat the oxidized bitumen 115/15 to 170 °C until it fully melts. Add PE wax gradually while stirring at 200–400 rpm. Continue mixing for 45 minutes to form a uniform, glossy mass. Add antioxidants or UV stabilizers (0.2–0.3%) near the end of mixing. Cool slowly to around 130 °C, then fill into steel drums or IBC containers. Following these steps ensures stable viscosity, good flow, and consistent film quality.

Why Quality Matters

The quality of bitumen with PE wax depends entirely on the purity of its ingredients. High-grade oxidized bitumen and refined polyethylene wax provide smoother melting, cleaner color, and longer shelf life. Inferior materials reduce gloss and increase costs. For dependable quality and verified specifications, industrial buyers trust ATDM Co., a recognized global producer of bitumen and wax derivatives.

ATDM Co. – Your Trusted Partner in Bitumen and Wax Solutions

ATDM Co. supplies premium oxidized bitumen 115/15 and PE wax (PEK135) that meet ASTM and ISO standards. With decades of manufacturing and export experience, the company guarantees quality, consistency, and technical support. Because ATDM Co. controls every step—from refining to packing—customers enjoy competitive prices and reliable delivery. Moreover, its experts provide formulation advice to help clients produce the best possible bitumen with PE wax blends. ATDM Co. offers flexible packaging options such as 20 kg PE bags for wax and 180 kg steel drums for bitumen. It ships globally from Iranian ports like Bandar Abbas and Bushehr, complete with export documents (COO, BL, MSDS, TDS). With ISO-certified systems and professional logistics, ATDM Co. ensures your materials arrive safely and on time.

How to Order from ATDM Co.

Ordering bitumen with PE wax from ATDM Co. is quick and simple. Contact the sales team via [email protected] or visit www.atdmco.com. Provide your required grade, packaging, and destination port, and receive a quotation within 24 hours. ATDM Co. offers both FOB and CNF prices, flexible loading options, and inspection reports. The company also supports long-term supply contracts and private-label production for distributors. Whether you order a single container or recurring shipments, ATDM Co. guarantees consistent quality, efficiency, and professional service.

Final Thoughts

Mixing bitumen with PE wax is one of the most effective ways to enhance coating strength, flexibility, and gloss. This advanced formula delivers water resistance, thermal stability, and long-lasting protection. Moreover, choosing ATDM Co. as your supplier ensures premium-grade materials, technical expertise, and dependable logistics. As a global leader in oxidized bitumen and polyethylene wax, ATDM Co. continues to provide quality, innovation, and reliability to industries worldwide.