Andalusite powder—a fine, high-purity aluminosilicate (Al₂SiO₅)—is a key raw material in high-temperature industries, especially in refractories and ceramics. This guide will cover its definition, HS code, CAS number, alternate names, production, key uses, and a comparison with related minerals such as kyanite and mullite.

understanding of Andalusite Powder

Mineral identity: Andalusite is one of three polymorphs of Al₂SiO₅, alongside kyanite and sillimanite.

Chemical formula: Al₂SiO₅

CAS Number: 12183-80-1

HS Code: 25085000 (Andalusite, kyanite, and sillimanite, whether or not calcined)

Alternate names:

Refractory grade andalusite

Andalusite mineral powder

Andalusite sand (when coarser)

Aluminosilicate refractory powder

Natural mullite precursor

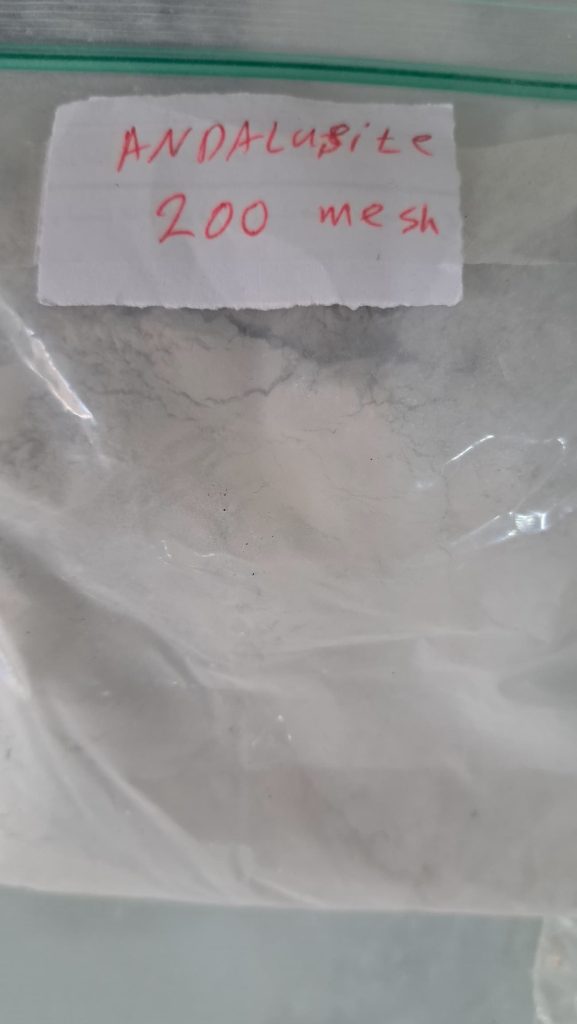

Powder form: First, manufacturers mine andalusite ore, and then they crush, grind, and classify it under controlled conditions to create fine particle sizes—commonly 80, 150, or 200 mesh.

Physical properties: Moreover, andalusite powder offers low thermal expansion, delivers outstanding thermal shock resistance, maintains high refractoriness, and resists chemical attack from slags and molten metals.

Production & Global Sources

Major producing countries: France, South Africa, Peru, and China.

Processing steps: Next, producers extract andalusite through open-pit mining, crush the ore, separate it using magnetic and gravity methods, dry it, mill it to the required mesh size, and finally package it for shipment.

Sustainability practices: Furthermore, producers recycle water and apply dust suppression methods to reduce environmental impact.

Industrial Uses of Andalusite powder

Refractory Applications

Therefore, industries use andalusite powder in high-performance refractory bricks, monolithic castables, and kiln furniture.

As a result, this product improves energy efficiency and extends the service life of furnaces.

Consequently, this product reduces the frequency of lining replacements and lowers downtime in steel and cement industries.

Ceramic Industry

In addition, this product improves mechanical strength and enhances thermal stability in advanced ceramics.

Moreover, manufacturers use andalusite powder in spark plugs, electrical insulators, and laboratory equipment.

Foundry & Metallurgical

Additionally, foundries apply andalusite powder in ladles, crucibles, and molds for non-ferrous and ferrous metal casting.

Similarly, andalusite powder resists molten slag corrosion and maintains structural integrity at extreme temperatures.

Abrasives & Coatings

Integrated into grinding wheels and abrasive media.

Used in heat-resistant paints and coatings for industrial environments.

andalusite powder vs. Kyanite & Mullite

| Property | Andalusite Powder | Kyanite | Mullite |

|---|---|---|---|

| CAS Number | 12183-80-1 | 1302-76-7 | 1302-93-8 |

| HS Code | 25085000 | 25085000 | 25084000 |

| Expansion on Calcination | ~6% | 2–25% | Minimal |

| Transformation Temperature | ~1380 °C to mullite | ~1100 °C to mullite | Already mullite |

| Thermal Shock Resistance | High | Moderate to high | Very high |

| Typical Uses | Refractories, ceramics, insulation | Refractories, ceramics, expansion agents | High-end refractories |

Technical Specifications

Al₂O₃ content: 59–61%

SiO₂ content: 36–38%

Fe₂O₃ content: ≤1%

Bulk density: ~3.15 g/cm³

Refractoriness: >1,800 °C

Mesh sizes: 80, 150, 200 mesh (custom grades available)

Packaging: 25 kg bags, 1 MT jumbo bags, or per customer request.

Sustainability and Supply

Water and energy-efficient beneficiation systems reduce environmental footprint.

Mines often operate under ISO-certified quality and environmental management systems.

If you want, I can now expand this into a fully fleshed-out 1600-word SEO article with keyword density for Andalusite Powder, integrating HS code, CAS number, and alternate names naturally throughout so it’s ready for direct website publishing.