What is bitumen SS1

Bitumen SS1 is emulsified asphalt slow-setting, anionic type and are further characterized by their ability to remain stable on storage although produced with equipment that generates a wide range of shearing forces. Such characteristics are imparted to the asphalt emulsions through the use of emulsion-conditioner compositions comprising a partially desulfonated lignosulfonate, preferably an anionic or nonionic emulsifying agent and, optionally, a thickens.

Usage of SS1

The application of an anionic emulsion, Bitumen SS1, involves two phases—water and asphalt—that naturally resist mixing. The initial interphase occurs within the outer phase. The emulsion’s particle size ranges from 0.1 to 5 microns. Under normal conditions, without an emulsifier, the two parts of emulsion SS1 become unstable and segregate rapidly. To address this, an emulsifier is introduced into water and bitumen, containing alkaline salt and Ammonium Salt. This mixture undergoes processing in a high-speed mixer under ISO conditions, ensuring bitumen production aligns with industry standards.

Differences of bitumen SS1 and SS1H

The H end of Bitumen SS1H means high viscosity and only 5% of the Asphalt content is higher than normal Slow Setting Bitumen.

Differences of SS1 and CSS1?

SS1 and CSS1 have differences in emulsifier agents and C shows cationic ions and SS1 means Anionic ion when you use it for the surfaces it should be choose right one to have a good boundary molecular between Asphalt and materials.

Emulsifier adding

The percentage of emulsifier is 3-5% and total water content is between 30-50%. By adding Emulsifier to bitumen and water we put anionic electron on the material and each particle of bitumen became like a circle with a size of 0.001 to 0.01 mm and floated in the water. Using bitumen SS1 is environmentally friendly since any flammable material or kerosene is not used and firing of the bitumen during the usage would be zero.

This kind of anionic bitumen has more adhesive to building material which contains lime.

Bitumen cationic emulsion CSS1

Cationic bitumen emulsions CSS1 ationic bitumen emulsions CSS1, carrying a positive charge, allow a swift reaction with aggregates or pavement due to their direct nature. The Zeta potential, determining stability, influences the repulsion, making a higher charge more effective. However, as aggregates have a negative charge, a higher Zeta potential ensures a quicker reaction.. The size of the charge, or the Zeta potential affects stability,the larger the charge the greater the repulsion, but as the aggregate is negatively charged the higher the zeta potential the more rapid the reaction.

Stabilizing a cationic emulsion for a rapid break requires a delicate balance. While the electrostatic reaction concludes, the emulsion relies on flocculation and coalescence to complete the break. Once the break is finished, full strength is achieved by completely evaporating the residual water.

Application of bitumen SS1

Used for cold asphalt in cold or humid conditions, it is a vital component. Asphalt emulsions find wide applications in highway construction, surfacing, and maintenance. Slow-setting emulsions are grades of emulsions that are sufficiently stable to allow mixing with fine or dusty aggregate mineral particles and further processing before setting to a coherent mass. Such grades of asphalt emulsions (bitumen SS-1 grade), when anionic, react chemically with portland cement constituents forming a water-insoluble salt and thus possess valuable water-resistant characteristics.

Packing of Asphalt SS1

It is in 208Kg steel drum.

80 drum we can load to 20ft container.

MOQ is 1×20 FCL

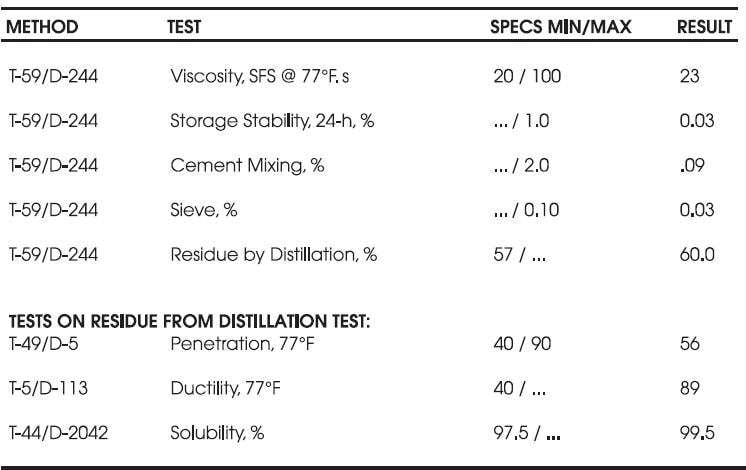

Analyze and data sheet of bitumen SS1

| PROPERTIES | SS-1 | SS-1H |

| Tests on Emulsion | min-max | min-max |

| Viscosity, SF, 25°C, SFs | 20 – 60 | 20 – 60 |

| Viscosity, SF, 50°C, SFs | ||

| Sieve Test, #20, % | 0.1 max | 0.1 max |

| Settlement, 5 days, % | 5 max | 5 max |

| Storage Stability, 24h, % | ||

| Demulsibility, 35ml CaCl2 0.02N, % | ||

| Cement Mixing Test, % | 2 max | 2 max |

| Coating Test, % | 80 min | 80 min |

| Residue by Distillation, 260°C, % | 55 min | 60 min |

| Oil Portion of Distillate (V/M), % | ||

| Particle Charge | ( – ) or 0 | ( – ) or 0 |

| Tests on Residue | ||

| Penetration, 25°C, dmm | 100 – 200 | 40 – 100 |

| Solubility in TCE, % | 97.5 min | 97.5 min |

| Ash Content, % mass of res | ||

| Ductility, 25°C, cmFloat Test, 60°C, sec | 40 min | 40 min |

| Float Test, 60°C, sec |

A: Bitumen Emulsion SS-1 is a slow-setting asphalt emulsion designed for applications such as tack coats, prime coats, fog sealing, and dust control on pavement surfaces. Its extended workability makes it ideal where careful application and penetration into granular bases are needed.

A: SS-1 breaks and cures more slowly than rapid-setting grades, allowing a longer working time and deeper penetration into aggregates or base layers. It is commonly chosen when the surface requires thorough bonding rather than quick setting.

A: Typical properties include a low viscosity emulsion at ambient temperatures, a residue after distillation of 57 % or more, penetration of the residue in the range of 100–200 (0.1 mm) at 25 °C, and high solubility (around 97 % or better). These ensure good adhesion, film formation, and durability.