Meaning Of Steel Rebar?

Steel rebar, also known as reinforcement bar or reinforcing steel, is a crucial material used in construction to enhance the tensile strength of concrete structures. Concrete is strong in compression but weak in tension, making steel rebar essential for improving its structural integrity. It is typically made of carbon steel and is available in various shapes and sizes to meet different construction needs. If you are looking for a steel rebar supplier, it is essential to choose one that provides high-quality Iran Steel Rebar and meets industry standards.

Properties of Steel Rebar

Steel rebar possesses key mechanical and physical properties that make it an excellent reinforcement material:

- High Tensile Strength – Provides additional support to concrete structures.

- Corrosion Resistance – Certain types, like epoxy-coated or stainless steel rebar, offer enhanced protection against rust.

- Ductility – Can be bent and shaped according to construction needs.

- Bonding Ability – Deformed rebar adheres well to concrete, preventing slippage.

- Thermal Expansion – Expands at a similar rate to concrete, reducing the risk of cracks.

Applications of Iran Steel Rebar

Steel rebar is widely used in various construction projects, including:

- Residential Buildings – Strengthening foundations, walls, and slabs.

- Bridges and Highways – Providing durability against heavy loads and environmental factors.

- Industrial Structures – Used in factories and warehouses for strong frameworks.

- Dams and Water Treatment Plants – Withstanding water pressure and preventing structural failures.

- Tunnels and Railways – Reinforcing underground structures to maintain stability.

Steel Rebar Grades

The grade of rebar is determined by its yield strength (measured in MPa or ksi). Common rebar grades include:

Grade | Yield Strength (MPa) | Yield Strength (ksi) |

Grade 40 | 280 MPa | 40 ksi |

Grade 60 | 420 MPa | 60 ksi |

Grade 75 | 520 MPa | 75 ksi |

Grade 80 | 550 MPa | 80 ksi |

Grade 100 | 690 MPa | 100 ksi |

Grade 120 | 830 MPa | 120 ksi |

- Grade 40 & 60: Common in residential and commercial construction.

- Grade 75 & 80: Used in heavy infrastructure, such as bridges and high-rise buildings.

- Grade 100 & 120: High-strength rebar for special applications like seismic-resistant structures.

Types of Iran Steel Rebar

Different types of rebar are used based on their material composition and intended use:

a) Carbon Steel Rebar (Black Rebar)

- The most common type.

- Strong but susceptible to corrosion.

- Used in general concrete reinforcement.

b) Epoxy-Coated Rebar

- Carbon steel rebar coated with epoxy for corrosion resistance.

- Used in marine environments, bridges, and roads.

c) Galvanized Rebar

- Zinc-coated for better corrosion resistance than epoxy-coated rebar.

- More expensive but lasts longer in corrosive conditions.

d) Stainless Steel Rebar

- Highly resistant to corrosion.

- Used in extreme environments (e.g., chemical plants, coastal structures).

- Most expensive type.

e) Glass Fiber-Reinforced Polymer (GFRP) Rebar

- Non-metallic, lightweight, and non-corrosive.

- Used in environments where metal corrosion is a major concern.

- Expensive and has lower strength than steel.

f) Welded Wire Fabric (WWF)

- Made of welded steel wires in a grid pattern.

- Used in slabs, walls, and sidewalks.

g) European Rebar

- Made of manganese-based steel.

- Flexible but not ideal for earthquake-prone regions.

Rebar Sizes (Common U.S. and International Sizes)

Rebar sizes are labeled by a number representing the diameter in eighths of an inch (US) or in millimeters (international):

US Size (#) | Diameter (inches) | Diameter (mm) |

#3 | 0.375″ (3/8″) | 10 mm |

#4 | 0.500″ (1/2″) | 12 mm |

#5 | 0.625″ (5/8″) | 16 mm |

#6 | 0.750″ (3/4″) | 20 mm |

#8 | 1.000″ (1″) | 25 mm |

#10 | 1.270″ (1 1/4″) | 32 mm |

Choosing the Right Rebar

- For residential buildings: Grade 40 or Grade 60 black steel rebar.

- For highways and bridges: Epoxy-coated or galvanized rebar.

- For corrosive environments: Stainless steel or GFRP rebar.

- For earthquake-prone areas: High-strength steel (Grade 75+)

Difference Between Types and Sizes

The choice of steel rebar depends on the project’s requirements.

- Types: While deformed rebar provides better bonding, plain rebar is easier to cut and bend. Epoxy-coated and stainless steel rebars are ideal for environments prone to corrosion.

- Sizes: Thicker rebars offer more strength and are used in large-scale construction, while thinner rebars are used for minor reinforcements.

HS Code and CAS Code for Steel Rebar

- HS Code: 7214.20.00 (This is the common Harmonized System (HS) code for deformed steel bars used as reinforcement in construction.)

- Note: HS codes may vary slightly depending on the country, so it is best to check with local customs authorities for exact classification.

- CAS Number: Not applicable

- Steel rebar is a mixture/alloy rather than a single chemical substance, so it does not have a specific CAS (Chemical Abstracts Service) number. However, individual elements in steel (such as iron, carbon, and manganese) have their own CAS numbers:

- Iron (Fe): 7439-89-6

- Carbon (C): 7440-44-0

- Manganese (Mn): 7439-96-5

- Silicon (Si): 7440-21-3

- Steel rebar is a mixture/alloy rather than a single chemical substance, so it does not have a specific CAS (Chemical Abstracts Service) number. However, individual elements in steel (such as iron, carbon, and manganese) have their own CAS numbers:

Finding a Reliable Steel Rebar Supplier

If you are looking for a steel rebar supplier, it is important to consider quality, availability, and compliance with international standards. A trusted supplier should offer various types and sizes, ensuring fast delivery and competitive pricing.

For high-quality steel rebar, choose suppliers with a strong track record in the construction industry. A reputable steel rebar supplier should provide products that meet ASTM, BS, and ISO standards to guarantee reliability and safety.

In short

Steel rebar is an indispensable material in modern construction, providing strength and durability to concrete structures. Understanding its types, properties, and applications can help in selecting the right rebar for any project. Whether you need standard or specialized rebar, working with a trusted steel rebar supplier ensures quality and efficiency in construction projects.

- Mild Steel Rebar (Plain Bar) – Smooth surface, used in small projects.

- Deformed Rebar – Features ridges for better bonding with concrete.

- Epoxy-Coated Rebar – Corrosion-resistant, used in marine or high-moisture environments.

- Stainless Steel Rebar – More expensive but highly corrosion-resistant.

- Galvanized Rebar – Zinc-coated for moderate corrosion resistance.

- Glass Fiber Reinforced Polymer (GFRP) Rebar – Lightweight and non-corrosive alternative to steel.

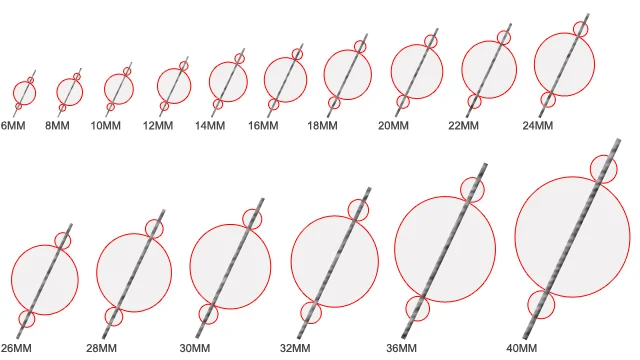

Rebar is available in different diameters, commonly ranging from 6 mm to 40 mm (¼" to 1 ½"), depending on the construction requirements.

Standard lengths are 6 meters, 9 meters, or 12 meters, but custom-cut lengths are also available.

Steel rebar prices fluctuate based on:

- Global steel market trends

- Raw material costs (iron ore, scrap steel)

- Demand and supply dynamics

- Transportation and import/export duties