Paint and sound acoustics Bitumen 75/35

Bitumen 75/35 is sound-isolating and shock-resistant paint for car, building, ship and train is prepared with this bitumen grade bitumen and good anticorrosion and adhesion, and not embrittling at low temperature

Uses of Bitumen 75/35

This high adhesive Bitumen composition will help reduce noise levels. These 75/35 were put into the original cars in the 1960\’s and we have been able to get hold of this material to provide a cheap and easy way to reduce vibrations within the car.

Paving by bitumen 75/35

the blown asphalt 75/35 products are for paving, roofing; also used in asphalt based paints for corrosion protection of metals, in lining public works structures, adhesives in electrical laminates, base for synthetic turf; typical uses for blown asphalt 75/35 include roofing, pipe coating, portland cement pavement, hydraulic applications, paint manufacturing.

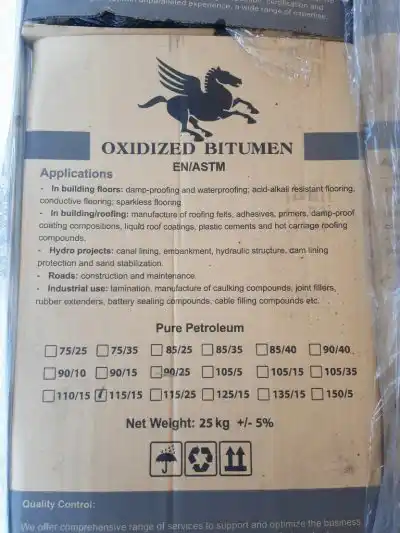

Packing of asphalt 75/35

The ATDM is manufacturer of blown asphalt 75/35 in various packing including kraft bag, meltable plastic bag, drum and bulk blown asphalt 75/35 from penetration grade bitumen, which is blown by hot air in a controlled process until the desired specification is reached. the ATDM oxidised bitumen 75/35 can be supplied in any grade and are designated by two numbers to indicate the softening point and penetration ranges. The blown asphalt grade 75/35 means softening point is 75°c and penetration is 35 desimillimiter is produced in compliance and conformity to ASTM standard and meets the following specification.

Guaranty/warranty of 75/35

ATDM guaranty the quality of blown asphalt 75/35 with arrangement of international inspector to check quality and quantity of the bitumen on each shipment during the loading to vessel and controlling the production by qc team via batch test report before shipping. ATDM guaranty the quality to meet with ASTM/EN 13304:2009.

Analysis of bitumen 75/35

75/35 | Specification | Test method ASTM/EN13304 |

Specific gravity @ 25/25 cg | 1.01/1.06 | D-70 |

Penetration @ 25 c | 30/40 | D-5 |

Softening point c | 70/80 | D-36 |

Loss on heating(wt) % | 0.2 Max | D-6 |

Flash point c | 250 min | D-92 |

Solubility is CS2(wt) % | 99.5 Max | D-4 |

Spot test | negative | A.A.S.H.O.T102 |

A: Oxidized Bitumen 75/35 is a semi-solid blown bitumen used in roofing membranes, waterproofing systems, pipe and tank coatings, industrial flooring, and adhesive production where heat resistance and strength are essential.

A: It is produced through an air-blowing process that increases its softening point and reduces penetration. This gives it higher rigidity, better heat resistance, and superior performance under heavy loads and high temperatures.

A: It typically has a softening point between 70 °C and 80 °C and a penetration value around 30–40 dmm, offering a balance of flexibility and strength for industrial use.