Bitumen 70/100 is a penetration-grade asphalt binder used for road construction, asphalt mixing, and waterproofing applications in moderate climates. It matters because it offers a balanced hardness and flexibility, which helps pavements resist cracking and deformation. Contractors, asphalt producers, and infrastructure buyers choose this grade when they need reliable performance, stable quality, and predictable behavior during mixing and laying.

What Bitumen 70/100 Is and How It Performs

Bitumen 70/100 is a petroleum-derived binder classified by its penetration value at 25°C. The penetration range of 70 to 100 (0.1 mm) shows a medium-soft consistency. Because of this balance, the material flows well during mixing yet gains enough stiffness after cooling.

As a result, it suits hot mix asphalt plants, manual laying, and mechanical paving. Moreover, it adapts well to countries with mild to warm weather. Many buyers select this grade when they want smooth workability without sacrificing durability.

Why Penetration Grade Matters in Asphalt Selection

Penetration grading helps engineers predict how bitumen behaves under load and temperature. A lower penetration means harder bitumen, while a higher value means softer material. Therefore, Asphalt 70/100 sits between hard grades like 50/70 and softer grades such as 80/100.

Because of this middle position, it handles traffic stress well while reducing the risk of thermal cracking. In addition, it supports consistent compaction during paving, which improves road lifespan.

Typical Applications of Bitumen 70/100

This grade serves many infrastructure and industrial needs. Its versatility makes it popular across public and private projects.

Common uses include:

Hot mix asphalt for highways and urban roads

Asphalt concrete for medium-traffic pavements

Road maintenance and resurfacing works

Waterproofing layers for foundations and roofs

Asphalt emulsions and cutback production

Because of its steady performance, contractors rely on it for both new construction and rehabilitation projects.

Advantages for Contractors and Asphalt Producers

Bituminous 70/100 offers several practical benefits on site and at the plant.

Easy handling: It pumps and mixes smoothly at standard asphalt temperatures.

Balanced stiffness: It resists rutting while maintaining flexibility.

Consistent quality: Stable penetration helps achieve uniform asphalt mixes.

Wide availability: It suits export markets with standard specifications.

Therefore, buyers reduce operational risks and gain predictable results across batches.

Technical Specification of Bitumen 70/100

The following table shows typical technical properties. Actual values may vary slightly by refinery and test method.

| Property | Test Method | Typical Value |

|---|---|---|

| Penetration @ 25°C | ASTM D5 / EN 1426 | 70–100 (0.1 mm) |

| Softening Point | ASTM D36 / EN 1427 | 42–49 °C |

| Ductility @ 25°C | ASTM D113 | ≥100 cm |

| Flash Point | ASTM D92 | ≥230 °C |

| Solubility in TCE | ASTM D2042 | ≥99 % |

| Loss on Heating | ASTM D6 | ≤0.5 % |

These parameters confirm suitability for standard road construction and waterproofing systems.

Compliance with International Standards

Manufacturers test Bitumen 70/100 according to recognized global standards. Most cargoes comply with:

EN 12591

ISO quality management procedures

Because of this compliance, the material integrates easily into government tenders and international projects. Engineers trust the data because laboratories verify each batch before shipment.

Quality Control and Production Process

Refineries produce this grade by carefully controlling vacuum distillation and air blowing conditions. Quality teams then test penetration, softening point, and purity.

Moreover, suppliers issue certificates of analysis with every shipment. This approach ensures traceability, consistency, and buyer confidence. As a result, procurement teams avoid unexpected performance issues.

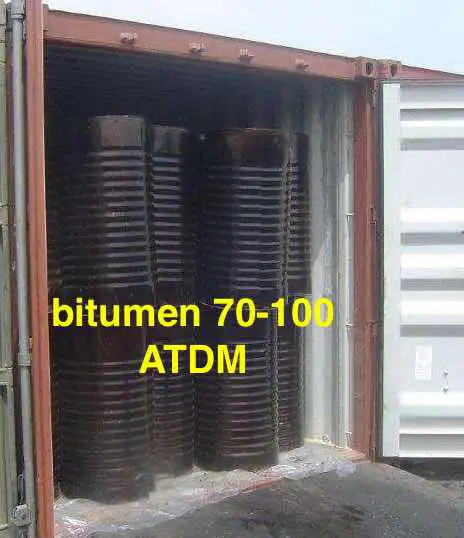

Packaging Options for Export and Local Supply

Bitumen 70/100 ships in several packaging forms to suit logistics and handling needs.

New steel drums (150 kg or 180 kg)

Jumbo bags with inner liner

Bulk shipments in heated tankers

Each option supports different unloading facilities and project scales. Buyers often choose drums for flexibility, while bulk supply suits large asphalt plants.

Storage and Handling Guidelines

Proper storage maintains quality until application. Keep the material in clean, dry tanks or sealed drums. Heat it gradually and avoid prolonged overheating.

In addition, protect containers from water ingress. Following these steps preserves penetration value and prevents contamination during transport and storage.

Logistics, Shipping, and Trade Considerations

Exporters usually offer this grade on FOB, CFR, or CIF terms. Shipment routes cover Asia, Africa, and the Middle East. Lead times depend on packaging type and port schedules.

Because Bitumen 70/100 remains stable during transport, it suits long-distance shipping. However, temperature control during loading and discharge remains essential for safe handling.

How Buyers Use This Grade in Asphalt Mix Design

Engineers select Bitumen 70/100 when designing mixes for moderate climates. They adjust aggregate grading and binder content to achieve target stability and flow.

As a result, pavements show good fatigue resistance and surface durability. This balance explains why many road authorities specify this grade in tender documents.

Supplier and Exporter Capabilities

ATDM supplies Bitumen 70/100 to contractors, distributors, and government projects with consistent quality and export-ready packaging. The company supports bulk orders, private labeling, and technical documentation for international trade.

Through controlled sourcing and inspection, ATDM ensures buyers receive material that meets stated specifications and project requirements.

Bitumen 70/100 is a softer penetration grade bitumen used in asphalt mixes, surface courses, and tack coats. It provides strong adhesion and flexibility for durable road performance.

Bitumen 70/100 is softer than 50/70 and slightly harder than 80/100, making it ideal for regions with moderate to cool temperatures and balanced traffic loads.

The softening point is typically between 46 °C and 54 °C, ensuring a stable balance between heat resistance and elasticity.