General description of semi refined paraffin wax 5-7% oil content

It means the slabs of semi refined paraffin wax 5-7% oil content can have 5% , 5.2% , 5.3% , 5.5% , 6.2% , 6.8% , 6.9% , 7% oil content, melting point can be minimum 58 c and maximum 64 c normally, semi refined paraffin wax 5-7% heavy grade (melting point 62-64 c) is used in hot weather countries like : south Africa , India, Pakistan , Kenya , UAE , Venezuela , Thailand , Saudi Arabia, Kuwait, Iraq, Bahrain , Jordan, Ghana , Colombia, Brazil, because if it is used in hot weather “petroleum wax will be melted and will make problem for the final product and also in packing and delivery process, leakage can make problem.

Semi refined paraffin wax 5-7% light grade (melting point 58-60 c); is used in mild and cold weather countries like Ukraine, Turkey , Germany, England, Russia, France, Italy, Norway, nether land, Finland, Switzerland, Sweden; Denmark, Canada , Australia , New Zealand.

Since the congealing point is about 2 degrees lower than the melting point, in light grade congealing of paraffin especially in candles needs lower weather degree.

Uses of semi refined paraffin wax 5-7% .

- candles; to make candles

- bottles; to seal top of the bottle by melted wax

- irons; to keep them smooth

- drawers; to lubricate

- handrails-to lubricate, rub the handrails with a bar of wax

- windows ; to keep them opening and closing smoothly

- zippers; to keep them from sticking

- steel or iron ; to prevent oxidation

- crayons

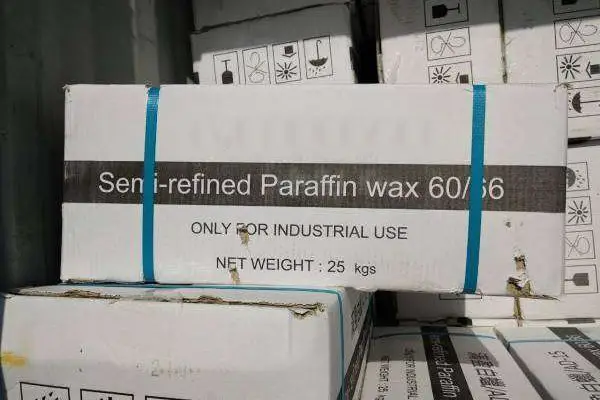

Packing of 5-7% oil content

this product is produced in 5 kg slabs which can be packed in carton , pp (poly propylene)bags or gunny and there is the possibility of palatalizing too.

Guaranty/warranty of semi refined

ATDM guaranty the quality paraffin wax with arrangement of international inspector to check quality and quantity of the semi refined paraffin wax 5-7% during the loading to vessel and controlling the production by QC by batch test report before shipping. ATDM guaranty the quality to meet with ASTM .

ANALYSIS OF PARAFFIN WAX 5-7% oil

| SPECIFICATION | TEST METHOD | RESULTS |

| Oil content | ASTM D-721 | 6 % |

| Melting point | ASTM D87-09 | 62 C |

| Color | ASTM D-1500 | 3-4 |

| FLASH POINT | ASTM D 93-13 | 300 C |

| SP.gr @ 25 C | ASTM D-190 | 0.82 gr/cm3 |

A: It means the wax retains between 5 % and 7 % free oil by weight after refining. This higher oil level results in a softer texture and greater flexibility, making it suitable for applications where cost-effectiveness and adaptability are key.

A: This grade is used in candle manufacturing, rubbers and tires as processing aids, packaging paper and board coatings, crayons and matches, general industrial lubricants, and non-food barrier coatings where ultra-high purity isn’t required.

A: Typical values include oil content around 5–7%, melting point approximately 58-64 °C (depending on light or heavy grade), specific gravity around 0.78-0.82 g/cm³, color white to faint yellow, and flash point around 270-300 °C.