Article

- Bitumen AC-10 AC-20 AC-30 AC-40|Bitumen AR 1000 to 16000

- Asphalt plastomer pellets

- Bitumen Class|Bitumen C160|bitumen C320|bitumenC450|bitumen

- Bitumen wax blended

- Jey oil company producing bitumen under name of Jey bitumen

- Pasargad bitumen (Pasargad oil company POC)

- bitumen SGS certificate grade 60/70 and 80/100

- Custom tax and HS code of bitumen in different country

- Bitumen conference

- Bituminous asphalt

- bituminous mixture

- tarmac road surface pavement

- Hot mix asphalt concrete HMA HMAC

- Bitumen water seal

- bitumen waterproofer

- Bitumen water repellent

- Slurry bitumen sealing

- bitumen sealant

- Scrim bitumen tape

- Roof seal bitumen

- Bitumen roof repair

- Liquid rubber

- Bitumen dam seal

- Dam proof membrane

- European bitumen association

- Asphalt roofing environmental council

- Asphalt paving environmental coucil

- Asphalt institute

- Asphaltic bitumen

- Bitumen cap sheet

- Bitumen building paper

- Bitumen adhesive

- Bitumen binder

- Bitumen solution

- Bitumen shingles

- Bitumen polymer sheet

- Bituminous putty

- Bitumen impregnated softboard

- Bitumen felt

- Bitumen based coating material

- Bitmac

- Bitumen 60/70 price in UAE

- How to test loss on heating of bitumen

- How to test water content of bitumen

- How to test float of bitumen

- How to test flash point of bitumen

- How to test viscosity of bitumen

- How to test specific gravity of bitumen

- How to test softening point of bitumen

- Ductility test of bitumen

- Penetration test of bitumen

- Bitumen suppliers in UAE, Dubai, Abu Dhabi

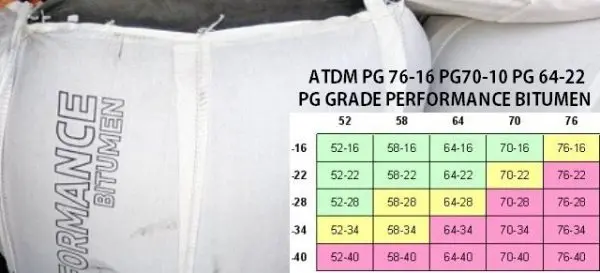

What is bitumen PG grade (bitumen performance grade)

Bitumen PG grade PG70-16 PG70-10 PG64-16 PG64-22 and PG58-34

is performance grade of bitumen which is replaced to all other old style grade of bitumen to work easily on high temperature and resist to break in low temperature.

This grades is American standard and after road authority recognized penetration grade and viscosity grade still has problem of stability during high temperature and low temperature brought new technic and standard to bitumen market which is focus on ageing of asphalt during 5 years.

What is the deference between bitumen PG70-16 PG70-10 PG64-16 PG64-22 and PG58-34

Number of PG is like bitumen PG 70-16 which is showing max temperature +70C and minimum temperature -16C or PG58-34 means it is stable in high temperature up to 58C and -34C the rest issue is same.

Test of bitumen PG grades

Test of PG grades is very critical also technical and doing in high pressure and temperature by special lab.

Our lab is approved by ISO 17025 and all other PG bitumen manufacturer sending sample to our lab to get approval.

In case range of temperature between minimum and maximum become large then need to add polymer to the bitumen to modify it by mix of SBS to help asphalt in summer time to have thoughts and in winter time elasticity which the normal asphalt in summer time become soft and in wintertime hard cold weather make it crack.

Oxidized bitumen is not work as PG

85 % of bitumen production (on the average about 90 mln tons of bitumen per year) is used as a binder in road construction. However oxidized and residual bitumen does not have the necessary properties to meet modern requirements to the pavement.

The most common way to increase the performance properties of oil bitumen (primarily, oxidized bitumen) is the use of various polymers as modifiers. Polymer modified bitumen compared to conventional bitumen has a number of significant advantages.

They are more elastic, flexible and durable, less sensitive to the temperature changes and aging, have better adhesive and cohesive properties.

SBS mixing with bitumen to make PG grade

Thermoplastic elastomers, particularly SBS, are most widely used as bitumen modifiers due to their complex action. They provide bitumen with high strength (the same as thermoplastics and thermosetting plastics), elasticity (as elastomers), heat resistance, adhesion, and improved low-temperature characteristics.

But the main reason that restrains thermoplastic elastomers prevalence is their high cost. An effective solution of this problem is their partial or complete replacement by cheaper polymers.

Modified Bitumen

A promising direction is the production of modifiers from by-products of fossil fuels thermo destruction, which contain a sufficiently large amount of unsaturated compounds.

Among mentioned by-products are \”heavy\” benzene and/or coal tar light fractions, obtained at coke plants and used for the production of indene coumarone resin. The latter one can be used to produce modified bitumen, which meets regulatory requirements and has extremely high adhesion (till 100 %).

Benefit of using bitumen PG grade

As mentioned above, due to its natural properties petroleum bitumen is not able to create the conditions for long-term operation of pavement under modern heavy duty traffic and adverse weather factors.

Therefore, in addition to providing the required quality and durability it is necessary to radically improve the physical and mechanical characteristics of these materials by complex modification with additives from a technical point of view, to create a bitumen based composite materials with a given set of properties only those substances may be applied, which meet the following requirements:

Use of bitumen PG grade

- They are not destroyed at the temperature of asphalt-concrete mixture preparation.

- They are compatible with bitumen during the mixing process on conventional equipment at the

- Temperatures usual for preparation of asphalt-concrete mixtures.

- In summer they increase the stability of bitumen (which is a part of the roadway) to the deformation impact loads without increasing its viscosity at the temperatures of mixing and laying and do not impart brittleness to bitumen at low temperatures.

- They are chemically and physically stable and do not change their properties during transport, storage, processing and operating conditions of pavement.

Bitumen performance grade PG 46 52 58 64 70 76 82 – 10 16 22 28 34 40 46

The bitumen performance grade (PG) asphalt composition is effective across a wide range of temperatures. An ideal PG modifier would be one which lowers the low end of this temperature range while raising the upper end of the temperature range.

It has been found that the addition of a high viscosity base oil or finished lubricant to the asphalt will decrease the lower and upper ends of the temperature range by about a one to one (1:1) ratio.

Cost effective asphalt

What is needed are more cost-effective ways to modify the asphalt with alternative PG modifiers which would be able to lower the low end of the temperature range while raising the upper end of the temperature range. The working temperature range determines whether a given grade of bitumen requires special manufacture or addition of a modifier.

For example, a bitumen PG 64-28 has a working range of 92° (64 + 28 =92). Usually, binders with a temperature difference of 92° or more would generally require some sort of modification

Bitumen specifications by performance grade (PG)

| PG 46 | PG52 | PG 58 | PG 64 | PG 70 | PG 76 | PG 82 | |

|---|---|---|---|---|---|---|---|

| Grade range | -34 to -46 | -10 to -46 | -16 to -40 | -10 to -40 | -10 to -40 | -10 to -34 | -10 to –34 |

| Average 7-day maximum pavement design temperature (°C) | < 46 | < 52 | < 58 | < 64 | < 70 | < 76 | < 82 |

| Minimum pavement design temperature (°C) | >-34 to >-46 | >-10 to >-46 | >-16 to >-40 | >-10 to >-40 | >-10 to >-40 | >-10 to >-34 | >-10 to >-34 |

| Original binder | |||||||

| Flash-point temperature, D92; min. (°C) | 230 | ||||||

| Viscosity, D 4402: max. 3 Pa × s, test temperature (°C) | 135 | ||||||

| Dynamic shear, D7175: G*/sind, min. 1.00 kPa; 25 mm plate, 1 mm gap; test temperature at 10 rad/s (°C) | 46 | 52 | 58 | 64 | 70 | 76 | 82 |

| Rolling thin film oven residue (T 240) | |||||||

| Mass loss, max. % | 1.00 | ||||||

| Dynamic shear, D7175: G*/sind, min. 2.20 kPa; 25 mm plate, 1 mm gap; test temperature at 10 rad/s (°C) | 46 | 52 | 58 | 64 | 70 | 76 | 82 |

| Pressure ageing vessel residue (PP 1) | |||||||

| PAV ageing temperature (°C) | 90 | 90 | 100 | 100 | 100 (110) | 100 (110) | 100 (110) |

| Dynamic shear, D7175: G* × sind, max. 5000 kPa; 8mm plate, 2 mm gap; test temperature at 10 rad/s (°C) | 10 to 4 | 25 to 7 | 25 to 13 | 31 to 16 | 34 to 19 | 37 to 25 | 40 to 28 |

| Creep stiffness, D 6648: S, max 300 MPa; m-value, min. 0.300; test temperature at 60 s (°C) | –24 to –36 | 0 to –36 | –6 to –30 | 0 to –30 | 0 to –30 | 0 to –24 | 0 to –24 |

| Direct tension, D6723: failure strain, min. 1.0%; test temperature at 1.0 mm/min. (°C) | –24 to –36 | 0 to –36 | –6 to –30 | 0 to –30 | 0 to –30 | 0 to –24 | 0 to –24 |